We continue this tale of Van-Related Hosiery with building out the intake and exhaust paths. At this point, I’ve statically tested the oil feed and return system (running the engine and making hehe snail sounds) but to actually go anywhere I have to make sure the charge air can get into the engine.

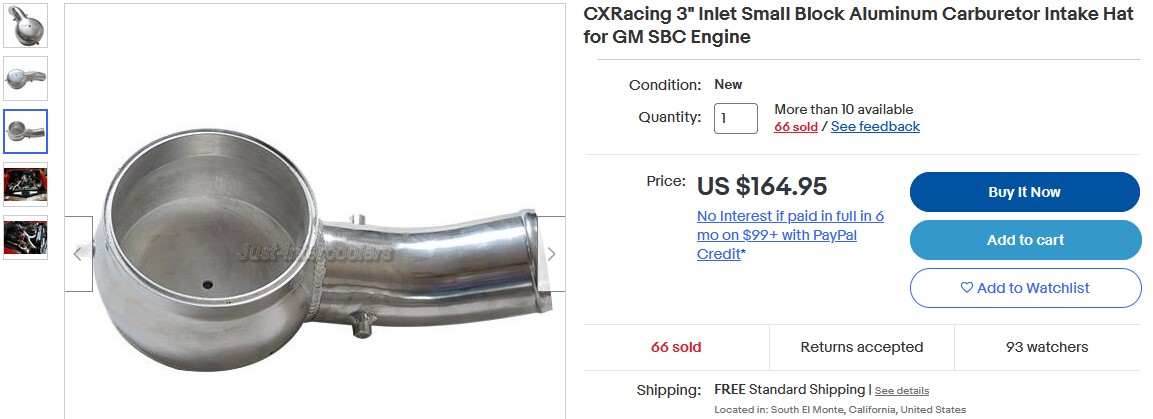

As usual, the choice was between make or buy. I was able to find inexpensive (ish) “intake hats” sized for common carburetor air cleaners. These would have fit, since the IDI also has a circular ~5 inch ring to seat the air filter.

The other choice was bespoke IDI-specific products such as the welded intake adapter from Classic Diesel. Either option meant I had to break out the single tube into a dual configuration using one of those fancy silicone tees/elbows. I mean, both seemed like perfectly viable paths forward.

That, my friends, is why I’m not buying one of those. Remember the whole point of this project is to be unreasonable. With most of a spool of Markforged Onyx left over, you probably see what’s coming.

Yup, here we go! Time to whip together a design for a dual-intake turbo hat for my 2 inch Slinkyhose. The upside of doing this is I could put the inlets anywhere I wanted, corresponding to the clearest path upward from under the floor.

The design isn’t complex. First I modeled a large dome that’s the size of the air intake adapter ring, then made two tangential cylinders outwards at the diameter I needed. I used a Shell operation to make a constant 5mm wall thickness, then made a revolution feature for the “bead” to capture the Slinkyhose.

More interesting was making a spot that will eventually house the pressure take-off points for wastegates and boost readouts. I wanted to make sure to model it in, since you can’t really drill a hole in it when done.

On top of that, I wanted it to not compromise the top surface (it’s not a perfect dome) and to span many layers at different angles for strength. The area would have multiple perimeters being laid down, and if I threaded it afterwards, the threads will grab many of those perimeters across layers.

So putting it at an angle, tangent to the dome, was the choice here. This required a bit of setup geometry, such as making a cross-section sketch to reference an extrusion plane from.

Once the plane was defined using the angled tangent line, then I could make the feature itself

The hole and its flat boss were made very large because I was originally intending to find an orientation where I could print this thing using it as the bottom, using no support lattices. If I really had it my way, it would allow the overhanging round beads at the inlets to be printed supportless as well.

The Markforged printers are basically the only printers I trust to pull these kinds of shenanigans off. A little bit of it I review in the Dumpster Miku post – it usually relies on trusting your printer to hang the whole part off one comparatively small surface, maybe with some support lattices at the very end to give you some reprieve.

Unfortunately with the inlets positioned the way they are, there was not a good solution to this. In retrospect, there is another geometric solution for the charge air hose in the engine bay that I didn’t see right away. So maybe a future revision will move these to a different angle of orientation.

I continued the extrusion inside as well to give the thru-hole area a little more meat. Remember, 15 PSI doesn’t sound like all that much, but there’s a lot of square inches pushing upwards and outwards here. At just over 19 square inches of circular area, that means about 300 pounds is going to be making the intake hat trying to explode off if I really go ham.

There was another slight modeling oopsie that I should have taken into account. Adding the circular beads would have made the uppermost point of the model not coincide with the flat circular face. Maybe I could have printed it open side down, but that was going to be a 70 hour print using almost as much material for support as the model.

So for now, I got rid of the beads. I’ll just… dunno, tighten the hose clamps more or something. That way, the entire thing can be printed “open side up”.

Print in progress! This was going to be about a day. If I were a crafty, well-equipped fabricator, I could probably bang out a welded aluminum intake hat in a few hours. But alas, I am not, and I also have other stuff to work on while this is finishing.

Finished without any issues!

There was a last-second feature I added which didn’t make it to the CAD screenshots. I added a ridge to the bottom-facing side to avoid printing severe overhang angles as it began the inlet circle profile. I figured I could just belt sand the ridges off afterwards, which is what’s shown above.

To make the 1/8″ NPT threads, I heated up a fitting with a heat gun to the point where I saw the plastic beginning to swell up. Then just cranked the fitting in all the way to heat-set the threads. This leaves a stronger hole than using a cutting tap to cut the threads into the plastic. The same concept is used in metals by using forming taps, which is common in soft metals like aluminum.

The heat-forming fitting was replaced by a haphazard Tee splitter made of a tee block and two right angle fittings. They sell the correct thing, I just had these on hand and burnouts now good ideas later, etc.

Test fit! A big fender washer holds the fort down from above using the OEM air cleaner bolt location. Remember: 300 something pounds.

If I wanted to be more legitimate, there would be a larger diameter thicker steel disc in place of that washer, backed up by stacked Bellevlle springs to achieve the level of tension I designed for.

> implies I designed any of thisHere’s what the slinkyhose fitup looks like! Notice that I’ve also adhered the intake hat to the manifold with plenty of orange silicone.

The left charge hose follows the auxiliary (rear) heater hoses downwards and meets the turbo compressor outlet very cleanly. Vantruck doesn’t have these aux heater hoses since it never had a rear section to begin with, so I’ll need to extend a small bracket out for the charge hose.

The right hose is a little weirder. It winds downwards using the valley between the heads and follows the transmission dipstick most of the way.

I then divert it away from the downpipe that feeds the right turbo. It looks really close from this perspective, but there’s about 1.5″ of minimum separation – good enough for now. The finished product will be heat-wrapped, too, for protection.

So that does it for the intake. As of this point, I could freely make hehe snail sounds to my heart’s content… and it really could be driveable, but I was sitting in a cloud of diesel smoke whenever it ran. That’s because I still need to route the exhaust path.

The Exhaust

Running the exhaust was to be a fairly simple exercise on the right side – the turbine outlet points straight backwards. The left side was going to be the problem here, because in my infinite wisdom I forgot the oil filter existed and therefore the left turbo had to (for now) exit forwards.

Hood stack? Maybe, but Vantruck isn’t going to have one of those, and I’d need to solve that geometry fitting issue later. For now, I needed to make a tight U-turn to get the left side exhaust to face backwards.

As I found out, most mandrel-bent exhaust pipe have a minimum bend diameter of about 3-4x diameter, so a 2.5″ pipe’s U-turn part would end up about 10+ inches across. This was too much to fit in the area I had between the engine mounting crossmember and the frame rail.

They do sell some really tight “turn stock” that seems to be made by hydroforming or stamping-then-welding or similar. I considered picking one of these up, and I will if Vantruck ends up having no other geometric solution.

But in the mean time, here is the content we all stay for:

Exhaust tips welded back to back. How’s THAT for “exhaust restriction”?!

One end gets cut off and the 2.5″ V-band flange is appended to it.

Ironically, this was actually just too tight, and I couldn’t get the flange to seat. Doing this at least let me see which way I can expand.

Alright, out comes the bandsaw again… I cut the weld apart and added a roughly 1.25″ wide chunk of 2.5″ exhaust pipe which I squished in the vise to emulate the oval cross section of the cut.

Don’t even start with me. I am above the law.

This setup does come a bit close to the radius arm bushing (on the very right), so I really want to make sure the final product can exfiltrate facing backwards. There’s a potential solution that involves rolling the turbo (with compressor inlet facing forward) around 45 degrees to clear the oil filter.

About this time, I got a Snail Snuggie in the mail. These kits come with a woven something or other (claimed to be fiberglass or other mineral cloth), some stainless steel ties and springs, and a big roll of exhaust pipe wrap. I’m not going to install this for now, but it’s a good look ahead. I do want Vantruck’s turbos wrapped up to avoid sudden heat shock like from standing water hitting a very hot turbine housing.

I didn’t want the turbos to be purely hanging off the relatively skinny-walled downpipes, but I also can’t rigid-mount them either. At least, not this driver’s side one. I cut a universal rubber hanger to the right length such that the clamps pull up on the pipe just a little. Enough to relieve the weight of the pipe section after it.

The right turbo could be rigid mounted to the transmission, it turns out. The transmission has a mounting ear or service stand hole that I could hang a quick bracket off.

Perhaps if I can find the other geometric solution for the left one, it can be supported by the transmission as well. There’s another one of these tabs on the forward left side.

This bracket was made from a section of 1 inch square steel tubing with two skew-drilled holes.

I think this mount will make it into “final production”. The job of this mount is also to relieve the weight of the turbo more than anything. Behind the respective mounting points, I’m going to use a segment of that flexible coil pipe before any other segments.

However, I didn’t have any on hand. At least not in 2.5 inch diameter. And so, with everything ELSE already hooked up and statically run a few times…

Oh, why the hell not. With the exhaust path at least vaguely pointing backwards, it was time to go to Autozone to buy your own parts!

Keep in mind the state of things right now: No increased fuel, wastegates left as they came (8 PSI – unverified), charge air hooked up, no exhaust path. It’s still just a van that makes hehe snail sounds. I strapped a camera to a tripod and recorded this POV drive first.

I did it with the interior doghouse off in order to keep the slinkyhose in my field of view. I could see the little segments inflating or stiffening up ever so slightly, but the fiberglass winding keeps it all in place. The Slinkyhose did not fly off the intake adapter, but that’s going to happen eventually as I step things up. The smoke filling the cabin was due to unfavorable winds pushing the exhaust right back in my face.

This was not a pleasant test drive.

Whatever, it works! Time to make it work in a little more civilized (just barely more) fashion. Using the Autozone’d exhaust parts, I cooked up some low production value Lake Pipes. On the left, a segment of slinky-pipe (as opposed to slinky-hose…. so many slinkies in this whole build!) makes the frame jump immediately aft of the radius arm bushings, from the U-turn.

On the right, just a short extension to bring the two exhausts roughly to the same distance along the frame.

Then a set of somewhat-matching 90 degree turns. On the right side, I do the flex-pipe frame jump after the extension; on the left, it’s already outside, so it’s rigid pipe all the way back. This was all just beat in with exhaust clamps.

I’ve gotten Snekvan to a stage where I could actually drive it places, so I did just to shake everything a few times. With the oil feed/return system, intake hosiery, and exhaust all seemingly solid (with completely OEM fueling levels), it was time to put some instruments on it. I ordered some cheap boost gauges and EGT probes from Amazon.

Without this information, I don’t know when it’ll explode, but with it, I’d be satisfied with bringing it to the very edge of explosion or slightly past it. Look, if it explodes, I’d at least want to know why… so the next try can back down just a little bit.