Yeah, so I actually went and printed off some of the parts I modeled up for this thing. I guess that means I’m committed to finishing it, even if it’s just a small scale model. The project has been temporarily designated μ-Chuckranoplan. All the image links say “fb” because I codenamed the design file “failboat”, which is probably what it’ll end up being anyway.

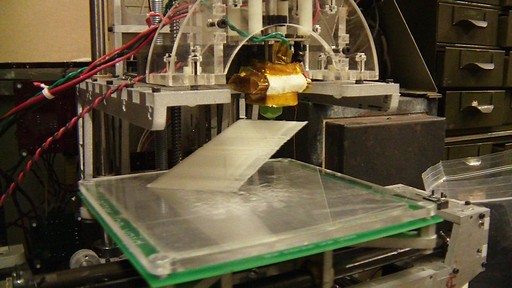

Here’s MaB taking a shot at the tail fin. The whole thing is essentially one continuous 45 degree overhang, so I enabled the cooling fan to prevent sagging (It’s barely visible behind the extruder above). I was also concerned about the narrow contact patch with the build platform causing the build to detach midway, so I angled it at 45 degrees to encourage symmetrical movement of the axes. It turned out quite well, so the rest of the airfoil surfaces will also be done this way.

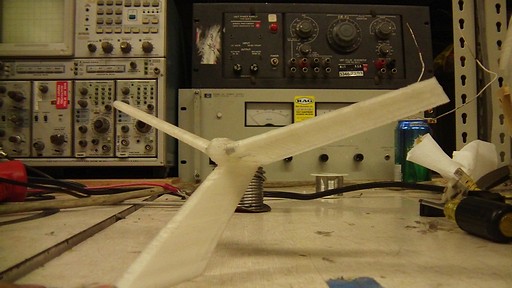

Blame the bad contrast on camcorders being very fail still cameras. Here’s the completed vertical tail with the “bubble” modeled all in one piece. There’s a small amount of sag at the top of the bubble, but overall it’s dimensionally accurate.

Next, I printed the two horizontal stabilizers . The whole assembly was smoothed over with some sandpaper before assembly. I just used some thin CA glue for the joints, since they did fit together quite well. Small chunks of aluminum rivets were cut and inserted into the 1/8″ diameter alignment holes to make sure the fins were at the right orientation.

Since the CA is intended just to align the wings, I’ll probably go over the joints with filled epoxy for added strength. The whole assembly is actually quite stiff.

And a better view of the area after the CA cured. I think I got the tail dihedral symmetric to within 1 degree….which, you know what, I don’t care any more beyond that.

Again, the sharp corners and unfilleted joints will probably be paved over with microsphere-filled epoxy.

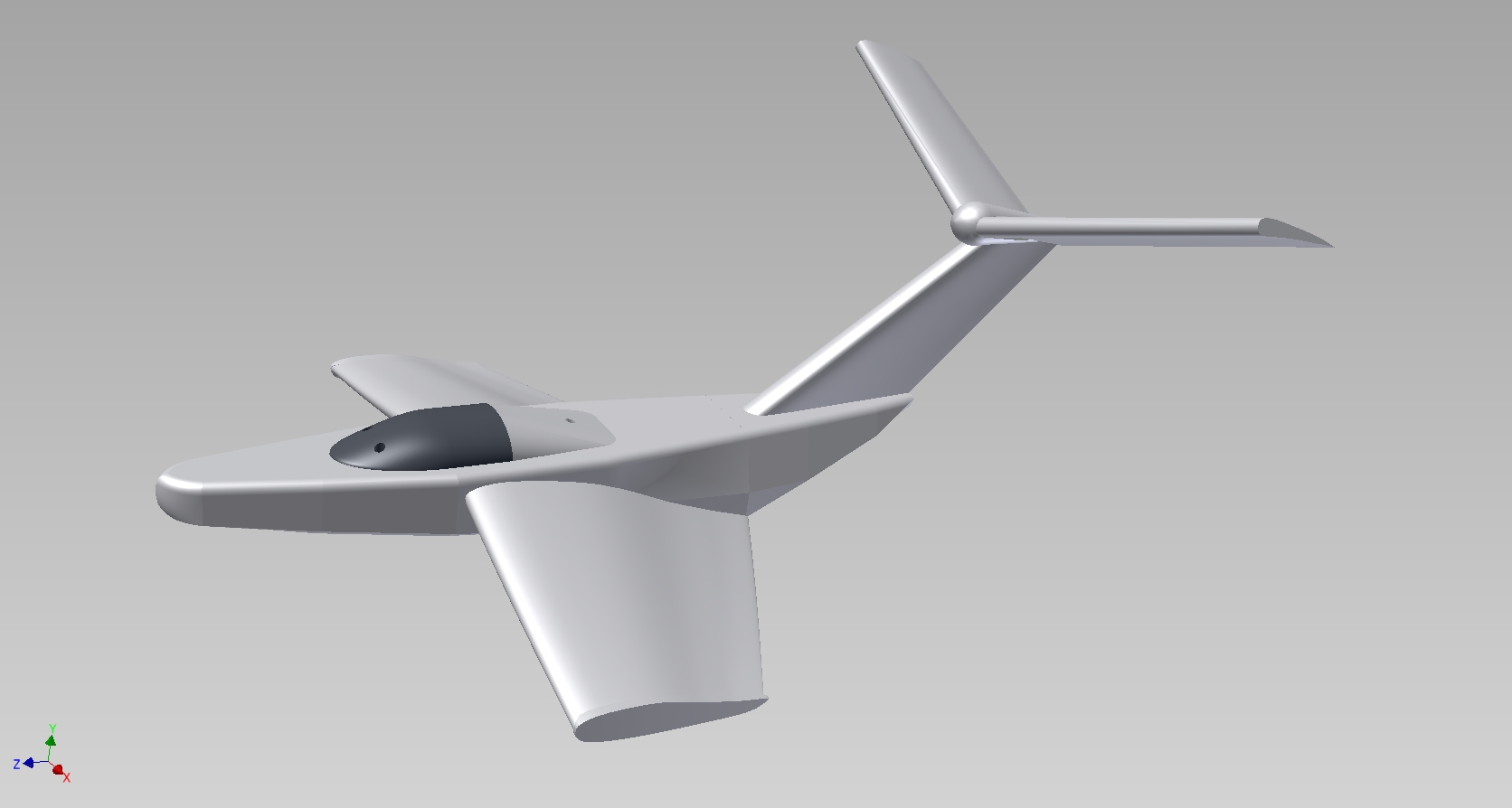

More to come! I’ve actually revised the design slightly such that the fuselage is printable all in the same orientation for height consistency. One issue I’ve run into related to that is the lack of surrounding temperature control for the print. Attempts to print the main wing are resulting in prints that vary in Z height by 2 or 3 mm, but given that the wingspan is the Z height here, the wings are unbalanced. I strongly suspect this is due to variations in temperature and heat dissipation causing varying amounts of shrinkage in the plastic as the print grows.

The “deck” is now completely flat – previously, the nose portion was tapered downwards. Thus, I can print the three pieces “top side down”. I’ve turned the canopy bubble into its own part. The idea is to print this part as a shell so it can cover whatever mess I make underneath when I core out the body sections to insert batteries and electronics into. The three holes in the canopy align with mating holes in the body sections so I can use the same chopped rivet hack to keep the canopy on.

While I still don’t have the mini ducted fans to model, I think at this point their pylons will sprout from the back part of the canopy bubble – the white part.

you must construct additional pylons.

it had to be said.

I knew someone was going to whip that out.