Since the last Überclocker update, a ton of work has been done on the bot. This past weekend, I purposefully trapped myself in the shop for the duration of the Snowmageddon Snowpocalypse Snowlingrad Snolocaust Great Leap Snowward Snowtorious B.I.G. which shut down most of New England for Friday through Sunday, to get as much done on Clocker as possible. I’m proud to say that at this point, the bot is driving (but not yet lifting). This following report will basically summarize the work of the past week or so, including all of this past weekend – otherwise, there’s going to be like 90 pictures!

I began by tackling basically the only menial machining task on the bot: making the Springy Legs. The “raw forms” were waterjet-cut from 3/4″ aluminum with the intention of finish machining.

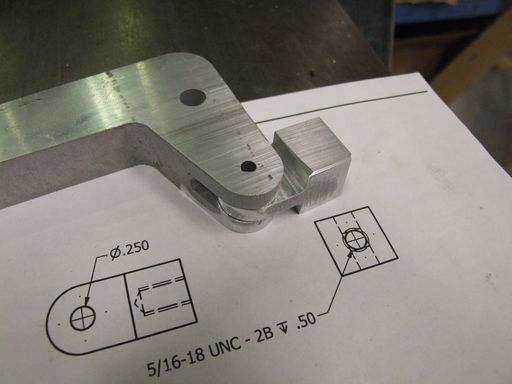

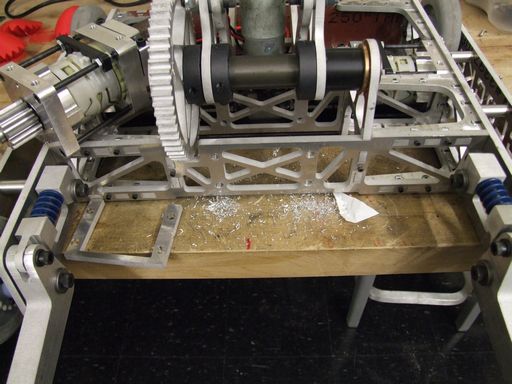

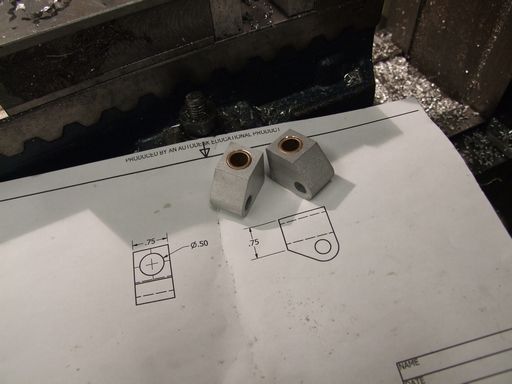

This is the stationary rear portion of my DIY shock absorbers. They just have a hole drilled through to hold a bronze bushing, which will interface with the “rod”, a shoulder screw.

The other two parts were a little more interesting. The trunion end of the shock absorber is doubly supported in the leg itself, so it meant I had to cut a roughly 0.8″ deep slot in the leg. I broke out, fortunately not actually breaking, my long-cut 1/4″ carbide endmill from the days when I collected tooling and carved it in 3 passes.

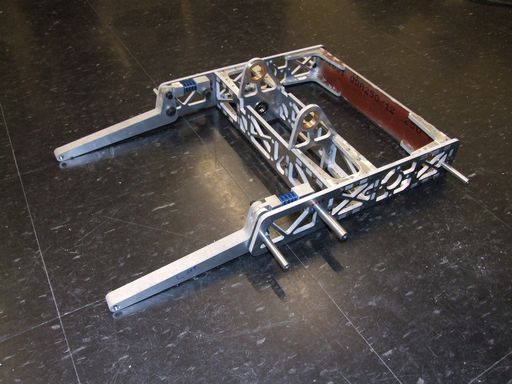

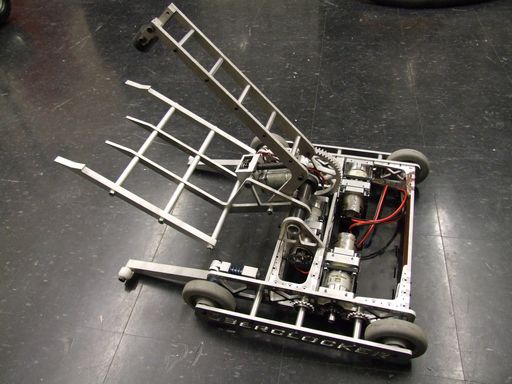

After most of the little menial machining objects were done, this is the state of the frame. I have a set of stiffer springs in case I find these too ‘soft’. If the bot lurches forward too much, it could hinder the lift by just keeling over at the very front of the legs.

From there, I moved to making the wheel hubs. These are based heavily on my design used in Clocker’s summer Gritty Reboot, but with a bigger Delrin center and larger diameter spacers for the larger sprockets. I started with a 1″ Delrin round and quickly whipped them out on Tinylathe from there.

Starting to reach Criticality (where a project can finally support its own weight)… I found a pile of nylon and steel washers to space the legs out properly. From there, plenty of blue Loctite was poured into the standoff-axles, forming the “permanent” side of the attachment. If I ever have to replace the legs, though, I’m kind of boned.

I christened this thing “Clockerboard” since I was riding it like a skateboard for a little while. The frame is extremely rigid, and the precision-ground aluminum standoff axles pair well with the Delrin hubs. The action is so smooth it might as well be on real bearings.

And the bottom plate goes on. I clearance-drilled the pilot holes in the bottom plate and made the attachment with #4 button headed screws. I normally despise buttonheads because of their super small 1/16″ hex key size, but they offer more bearing area (larger head) than the regular cap screws, which is better for the garolite’s structural integrity.

Starting from a 1″ diameter chunk of ceramic-coated (hard anodized, anyway) aluminum shaft, I drilled out the entire center with a long .75″ drill bit to save weight, then started putting the fork asesmbly together. In lieu of using retaining rings on the ends of the shaft, as originally planned, I decided to just machine spacers to span the gaps between forks in order to take up the axial slack. There was already going to be 3 different shaft collars constraining movement axially – a little snap ring wasn’t going to add that much more to the equation, and I could not be buggered to try and find the only grooving tool within 2 miles.

After cutting out some lengths of threaded rod, the fork comes together. This assembly is extremely rigid because of the sheer amount of preload I’ve put into this system through the three alloy steel threaded rods.

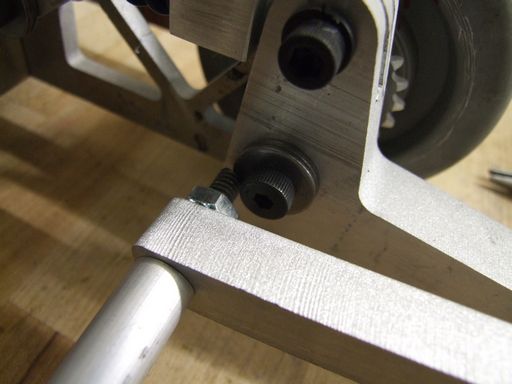

…unfortunately, I forgo that screws have heads.

The real story here is that the shoulder screw holding the leg on sticks out further than in the design because I added the spacing washers to give the leg a wider bearing area. I didn’t account for the extra width of a locknut compared to a regular nut, either. So the result, unfortunately, is just the hardware running into itself.

No problem – cutting the threaded rod exactly to length, and shortening the outer spacers 1/8″ each, gave enough slop room to clear the fork.

The modified clamp actuator goes on with, you guessed it, some more shoulder screws.

Mid last week’s pretend-o-bot, or thereabouts. This was just before the DeWuts showed up, so at this point I was stuck until I had motors. Luckily, Anonymous (…Chinese CNC shop) delivered.

While waiting for the DeWuts, I decided to take care of the rest of the menial machining tasks. I purchased a 1/8″ keyway broach to make the key cuts, and went to the Edgerton Shop to use a long-throw arbor press to cram the thing through the gears and sprockets.

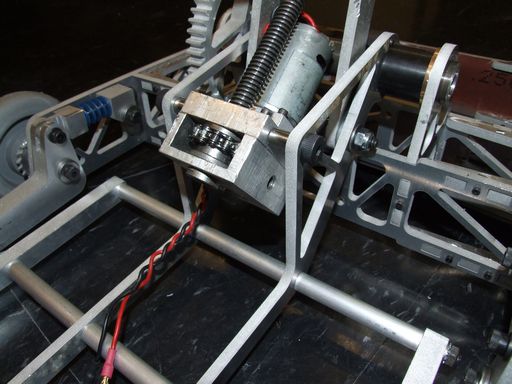

With the DeWuts having finally shown up, here’s one of the first pictures from the mid-snowstorm robot work: one drive motor with shaft trimmed and test mounted. To be honest, I was mostly distracted by finally being able to run Landbearshark in its native habitat to get substantial robot work done…

I also went ahead and mounted up the lifter motor. It’s attached to the frame through a big U-bracket which functions as a spacer, the bot cavity being 1/2″ wider than the motor.

One issue was that the final distance between mounting holes was basically 3.00 instead of 3.05″, the original anticipated design length. I’ll have to take measurements of multiple units in order to confirm the +/- deviation from 3.00″ I should report, but the 3 on Clocker are all pretty close. Either way, much clearance-drilling was required. I basically had to open these holes up to 5/16″ to make that fit.

Drive motors mounted. By this point, I think the snow depth was already 18″ and going. The pickup truck plows had given up, and heavy equipment was starting to roll through the streets.

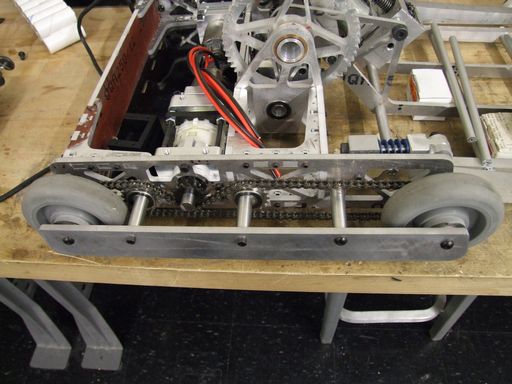

The last task of the night was routing the chains.

The chains on this version of Clocker are routed a little interestingly. On this (right) side of the bot, the chain wraps around the bottom of the sprocket. On the other side, though, the chain wraps over the top of the sprocket (and hence under the tensioner sprockets).

I did the chains up this way on purpose because the DeWalt motors are very heavily timed to favor one direction: the drilling/screwing-in direction, or counterclockwise. You rarely use a drill in reverse, so manufacturers squeeze a bit more forward power out of the motor by optimizing the brush timing for one direction.

In a traditional two-sided drive robot, the motors have to spin opposite directions to effect forward or backward motion since they are mounted mirrored from each other. In the DeWalt’s case, it seems to cause up to a 10% speed difference between sides – that means the robot will just pulll a huge wide turn the entire time you command ‘straight’. Clocker Remix, in fact, does this – it has never ‘driven straight’ in testing.

In practice, combat driving never really sees enough straight line travel for this to matter much, so most people just straight up ignore it. If I had the opportunity to make the bot more symmetric, though, I was going to take it. So, to power the bot forward, both motors in fact rotate counterclockwise as viewed from their own shafts. This is the favorable timing direction and the difference in speed is both audible (faster spinning, higher pitched) and visible (the bot is definitely slower going backwards).

As for the chains themselves, I incrementally dialed in the tensioners by running the chain for a few minutes, then moving the tensioners to tighter positions. Chains stretch a few % just by virtue of wearing in the first time, so this was critical.

That concludes the first round of work. In the past day, I’ve managed to wire up half of the bot, but that will be reported on shortly. Tomorrow I anticipate being able to start doing shakedown tests and figuring out what to tune before the event.