What a mouthful to say. But the tale of TB4.5MCESP1 is an epic one indeed, spanning 3 design changes, 4 weeks, and many nights toiling on Autodesk Inventor.

Originally, the course for TB5.0 was laid out as follows:

- A radical electromagnetic flipper design, using a mixed coilgun and linear motor-type design and all the force that Lorentz has to offer. If this fell through, the backup was…

- A spring-powered flipper using a leadscrew-based loading mechanism I came up with at 4AM, and if not that, then

- Making the 4-bar better and upgrading little reliability-related things inside the bot such that it just won’t randomly detonate. If all of this doesn’t happen for one reason or another, then the absolute last ditch plan was to just…

- Pound the dents out of MCE, strap in a new battery, and go to Motorama for shits and giggles.

After all was said and not done, I am (un?)proud to announce that I am now at stage 3 of the process.

Some scribbling on paper and ballparking of figures showed me that the amount of capacitance needed to deliver the suitable pulse of energy in the necessary length of time was something on the order of 20-30 farads at low voltages (30-50v) or 20,000-30,000uF at higher voltages (300+v). This was a problem, since I only have to much volume to stick capacitors in. Not to mention all the related issues with charging, degaussing of magnets when a 8 quintillion gauss external magnetic field suddenly appears, the fact that I almost have an EMP bomb in the arena (and how the fuck would you explain such a thing in a place like Boston anyway?), and other things such as no arm geometry really giving good performance.

Some scribbling on paper and ballparking of figures showed me that the amount of capacitance needed to deliver the suitable pulse of energy in the necessary length of time was something on the order of 20-30 farads at low voltages (30-50v) or 20,000-30,000uF at higher voltages (300+v). This was a problem, since I only have to much volume to stick capacitors in. Not to mention all the related issues with charging, degaussing of magnets when a 8 quintillion gauss external magnetic field suddenly appears, the fact that I almost have an EMP bomb in the arena (and how the fuck would you explain such a thing in a place like Boston anyway?), and other things such as no arm geometry really giving good performance.

The next idea seemed like it was going to work. I had cooked up a sort of “hair trigger” loading mechanism that could pull back a set of springs then let them go on the command of a servo or a poke from some other object. This was great, but the problem lay in everything else; that is, trying to locate and design the gearbox that would drive it, and trying to size the springs and arm travel. Sure, that stuff is doable, but the whole assembly was going to weigh 88,000 pounds and have six axles with 22 tires and a dump bed.

The next idea seemed like it was going to work. I had cooked up a sort of “hair trigger” loading mechanism that could pull back a set of springs then let them go on the command of a servo or a poke from some other object. This was great, but the problem lay in everything else; that is, trying to locate and design the gearbox that would drive it, and trying to size the springs and arm travel. Sure, that stuff is doable, but the whole assembly was going to weigh 88,000 pounds and have six axles with 22 tires and a dump bed.

Not to mention, of course, the extensive metal machining that would be required for both designs, especially with the spring flipper design, since I couldn’t just throw UHMW together to hold back 2000+ joules of capacitative energy or 800 pounds of spring force being released in a blink of an eye. Yes, it was überkill in many regards, but that’s how I roll.

And so, with the first snow of the season in late November, I realized that… Hey, Motorama was only TWO AND A HALF MONTHS AWAY! Time flies when you’re designing bots. I decided to drop the irrationally-exhuberant-but-would-work-better-when-i-take-some-real-engineering-classes designs and focus on making the 4-bar and the rest of the bot stronger and more reliable.

And so, with the first snow of the season in late November, I realized that… Hey, Motorama was only TWO AND A HALF MONTHS AWAY! Time flies when you’re designing bots. I decided to drop the irrationally-exhuberant-but-would-work-better-when-i-take-some-real-engineering-classes designs and focus on making the 4-bar and the rest of the bot stronger and more reliable.

This is an especially important choice considering that I would only have about one month out of that two to get any real work done, and only two weeks of that surrounded by MIT lab tools. Leaving out, of course, the two weeks between classes starting again and Moto weekend. We all know I’m just that much of an academic to drop all bot work during the semester.

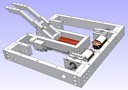

Designing SP1 was about as simple as dropping the new arm arrangement into MCE’s design drawing. However, there are several improvements I want to make to the assembly, some of which are visible in the renderings.

Designing SP1 was about as simple as dropping the new arm arrangement into MCE’s design drawing. However, there are several improvements I want to make to the assembly, some of which are visible in the renderings.

- The use of the waterjet-then-machine process as found on the scooter wheelmotor project. This enables the creation of more complex profiles while saving the machine time that would otherwise be used to nosh them out of metal. Since the arm pieces are long beams, clamping and setting up in a drill press or mill is still relatively easy. Also, creating the end radii would be so much easier and safer than holding the piece to a sander and hoping it doesn’t get shot across the room.

- The use of 2024 and 7075 aluminum in place of 6061 as used in many TB iterations. Those alloys possess significantly more strength than 6061 and I can buy them in sheets, so the waterjet can take care of some of the shaping.

- More effective use of material and the reinforcement of stress points. TB4.5’s arm was made out of one piece of 6061, milled into a sort of U-channel shape.

- The problem lay in the hinge pin holes, which caused material to be extremely thin at those locations, and the result was that a good punt from a drumbot bent and twisted the arm significantly.

- Also, the back of the arm had a huge cutout to pass over the final reduction gears, which only left 1/8″ of material on that side taking the stress.

So the current arm design makes use of slightly thinner portions of 2024 or 7075 on the main spans, but in a sort of C-channel configuration on each side. The material gets thicker vertically around the hinge pin holes. It has to bend somewhere, though, and I would rather that be the spans than at the hinge pins. The whole assembly is bound together side-to-side with fat aluminum standoffs. 7075 is known to be extremely strong, but also brittle, so maybe 2024 is a better choice.

I particularly liked the elegant appearance and modularity of TB4.5’s internals, with all the components mounted in Lexan assemblies. Modularity quickly went out the window as I hurried to finish the bot for BattlebotsIQ, but the Lexan plates still offered one more layer of protection between hardened steel blades and squishy electronics. Not to mention gray tinted Lexan just looked badass.

I particularly liked the elegant appearance and modularity of TB4.5’s internals, with all the components mounted in Lexan assemblies. Modularity quickly went out the window as I hurried to finish the bot for BattlebotsIQ, but the Lexan plates still offered one more layer of protection between hardened steel blades and squishy electronics. Not to mention gray tinted Lexan just looked badass.

It’s like having a dust cover AND a privacy curtain!

So that will return for MCE. Also worthy of note is the lithium polymer battery in its own little cage. I added more extravagance to the internal plates because polycarbonate can be laser-cut and the Media Lab conveniently has a bunch of laser cutters, which I have seen used on everything from cardboard to 3/4″ plywood to…. chocolate bars and graham crackers.

Also, I’m going to try some new ESCs from Dimension Engineering. The Sabertooth 2×25 and Syren 25 are both 25 amp controllers with burst ratings of 50 amps. What made them appealing was the compact size and the use of bottom-mounted driver chips. Victor 883s, although reliable and proven, are gigantic and relatively heavy. They took up alot of room that could have been used for other things. Other “small bot” ESCs have had overheating issues, and were hard to mount to a bigger heatsink – the Scorpion XL’s “stacked” driver chips and the Banebots 12-45’s double-sided surface mount design come to mind.

With the single-sided bottom-mounted motor drivers, I could mount everything to a big metal plate and have some leeway in heat dissipation. 25 amps is also a decent overhead for the drive motors, which should never pull more than 15 amps anyway, and the 50 amp burst rating of the single-channel controller should be enough to satisfy the arm duty cycle.

So I hope they work out. By the way, that’s not an actual 3D model of the controllers in the picture. No ESC I know of requires retaining rings.

Also returning is my reverse-switch, which is only off when a key is inserted into the slot. In the previous posted picture of TB4.5MCE, you can see the neon-pink key with “OFF” written on it.

Also returning is my reverse-switch, which is only off when a key is inserted into the slot. In the previous posted picture of TB4.5MCE, you can see the neon-pink key with “OFF” written on it.

Another problem with MCE that I am trying to mitigate in some way is the fragility of the wedge skirts. Perhaps it’s just a matter of shitty hinges, but they were all pretty loose by the end of IQ 2007. One even had to be bent back into shape.

Another problem with MCE that I am trying to mitigate in some way is the fragility of the wedge skirts. Perhaps it’s just a matter of shitty hinges, but they were all pretty loose by the end of IQ 2007. One even had to be bent back into shape.

Besides welding the rolled seams of the hinges shut, I also wanted to somehow decrease the strain on each hinge. One of these solutions was ditching the side skirts and making the front wedge one wide flap, such that severe impacts from the side would stress two hinges spaced a few inches apart rather than just one of them.

Here’s one idea, which runs the “crossbar” under the arm, such that the arm can reach the ground and also swing unimpeded. The disadvantage to this design is that the bot would have no offense if inverted – the wedges will not be able to swing down and at least act as plows.

Solution number 2 is to integrate the crossbar into the wedge, but this time, the arm itself will not contact the ground at all. This design allows either to pass over or under the other, so I’ll have some line of defense if the bot becomes inverted, but a major handicap while the bot is upright is that the arm…doesn’t reach the ground. I won’t be able to pick opponents off the ground; they will have to ride up the wedge first. This might be more trouble than it’s worth.

Solution number 2 is to integrate the crossbar into the wedge, but this time, the arm itself will not contact the ground at all. This design allows either to pass over or under the other, so I’ll have some line of defense if the bot becomes inverted, but a major handicap while the bot is upright is that the arm…doesn’t reach the ground. I won’t be able to pick opponents off the ground; they will have to ride up the wedge first. This might be more trouble than it’s worth.

Of course, one solution is to just leave it – just make the attachment better and use stronger materials. I used stock, cold-rolled steel piano hinge for attaching all the wedge skirts, and they could stand alot of improvement. Welding the rolled seams shut would prevent the “unfurling” of the hinge, and the use of washers or “uber-nuts” would distribute forces over a wider area rather than focusing it at the screw heads. The skirts could easily be 7075. In the end, anything is stronger than the UHMW it’s mounted to!

Of course, one solution is to just leave it – just make the attachment better and use stronger materials. I used stock, cold-rolled steel piano hinge for attaching all the wedge skirts, and they could stand alot of improvement. Welding the rolled seams shut would prevent the “unfurling” of the hinge, and the use of washers or “uber-nuts” would distribute forces over a wider area rather than focusing it at the screw heads. The skirts could easily be 7075. In the end, anything is stronger than the UHMW it’s mounted to!

I’ve also grown accustomed to the half-Biohazard look of TB4.5.

With the calm before the storm quickly passing, it’s time to forget design work and get ready to face the final boss(es), the final exams! If I triumph, I’ll post. If I lose…well, I’ll post anyway.

Bot on!

Your spring method has merit. I’m fairly certain a much lighter and simpler [but weaker] system can be made using torsion springs and a single appropriately shaped cam on the end of a high torque motor.