With the holiday and end-of-year business shutdowns finally ending, the steady trickle of parts shipments for Landmelonsharkpigbeartankboard is flowing once again. I’ve finally gotten my trippy PCBs in for Make-a-Bot too, but haven’t gotten the chance to make the heat spreading plate and test it yet. Otherwise, I got Segfault running once again, now with its own enormously overkill battery.

Overall not much to say, so let’s just start with the grocery list.

landbearshark

LBS is still a pile of parts that has been steadily increasing in size. The materials needed to start the entire project off are the aluminum plates, which have yet to arrive. Otherwise, I have essentially everything – motors, motor-side sprockets, chains and links, the four shock bodies, a whole mess of stainless steel hardware, most other drive components, and this cute little contactor.

Here’s what the whole mess looks like right now…

Still on the way for whatever reason are three 24″ x 24″ x 1/4″ aluminum slabs. Other frame materials are used in small enough quantities to just be scrounged.

The design has been filled out with the requisite t-nuts needed to hold the panels together.

Some minor touches are missing, including places to mount the rider-sensing switches. The contactor and other major electrical components are also homeless at the moment. I also need to make the “second deck” of electronics which will handle tasks other than motor control. I did collect a model of the Giant Red Key Switch, and it hangs out in the back.

If I’m lucky, the metal will arrive tomorrow and the frame can be cut out by the weekend. That’s really the only hard part.

(Okay, minus the electronics…)

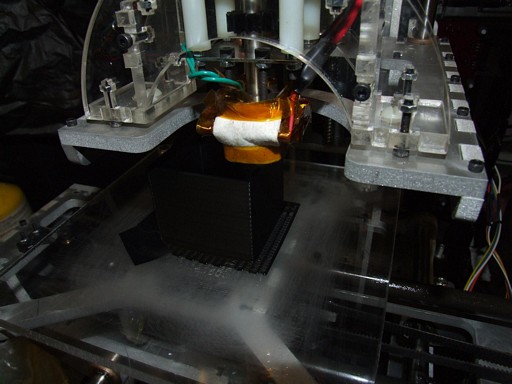

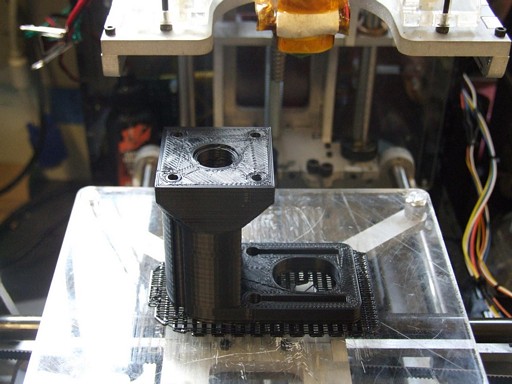

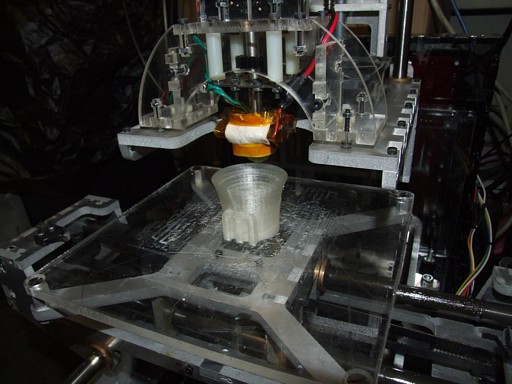

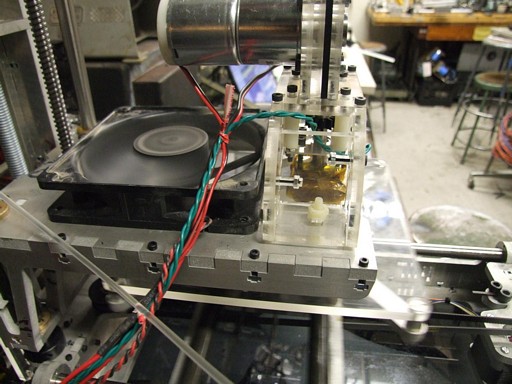

make-a-bot

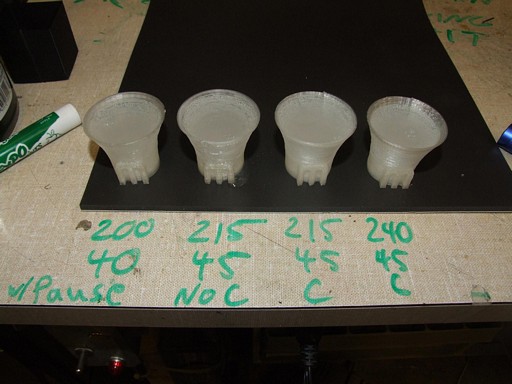

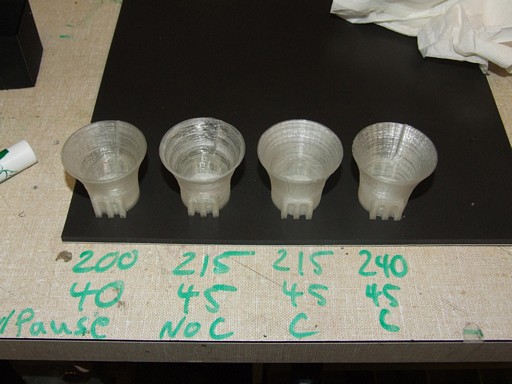

At last, the trippy PCB heaters!

Trriiiippy.

I made one change from the version I keep linking to – there’s a center hole in the board so I can wedge a thermistor between it and the aluminum heat spreader. You know, so I can actually find out the temperature of the working surface. Otherwise, the trace resistance checks out (the squiggles on the bottom side in the design were put there in case they did not…) I’ll need to cut a single square of aluminum for the heat spreader. The aluminum will then be thermal-epoxied (not bolted or sandwiched) to the top of the board.

I got two boards, but will only prepare one of them for now.

segfault

Poor Segfault.

No, I haven’t completely trashed it yet again. It’s been working, but always became weak after 30 minutes or so because all I had in it were two of Überclocker’s packs. It would usually just fall over after an hour. So after the term ended, I swore I would make a new battery just for it such that I can reliably bring it out for demos. Naturally, with the ennui of the break, I felt unmotivated to do anything. Additionally, during an unfortunate scooter-organizing incident, the cable leading to the control knobs was sheared off, so it was just one more impediment and grunt-work repair job I had to tackle before it could even work again.

So maybe I did completely trash it. Either way, I guess it counts as New Year’s resolution to repair Segfault? I’m not sure.

Here’s where it starts.

Ah, another brick of A123 26650 lithium nanophosphate cells; here, being prepared and tinned.

Segfault’s completely empty right side was just begging for a brutally large battery. I measured everything out and found that I could easily fit a 5 x 7 cell array. Since Segfault already demonstrated operation on 7S (about 23 volts), I’d have to make a pack that had 5 cells in parallel. This is more or less a 146% \m/etalpaKkK. With 5 2.2 amp-hour cells in parallel, the total watthours count of this pack comes out to be around 250. It ought to be enough to keep Segfault running for two hours or more.

The enormous \m/etalbraid makes a return on this pack. Grounding braid is now my staple “battery bar”, as shown by the \m/etalpaxXx themselves and RazEr rEVolution’s pack (and the Clockerpacks, and the monstrosity I made for Cold Arbor). Segfault will never draw enough current to overload these busbars, but hey – maybe one day this thing will be repurposed. Have to plan ahead, you know.

Soldering is discouraged on cells like this because of the risk of melting the polymer separator close to the terminal, which results in bad. If you’re very fast and have a soldering iron with a large tip (high thermal mass, effective thermal bath), it’s definitely possible. I stuck to my 3-second rule here – once the joint starts melting, I count 3 seconds to smash it down and add more solder. Once that time is up, I immediately move on to another cell, and don’t return to that one until I’ve visited the rest of the pack.

It’s probably not very legit, but I haven’t overheated a cell yet…

After the whole pack got busbraided, it was time to add the wires. There’s three heavy-gauge wire pairs coming out of the pack this time. The two off to the right interface with the existing double battery connector in Segfault. There’s no reason to have a double connector in the thing, but it’s the way I originally made it to accept the robot batteries.

The single cable to the left is only used for charging. But I guess it could be a third discharge port if needed.

I ordered JST-XH connectors in several different sizes from Digi-key, so I was actually able to make a legitimate balancing harness.

Now the fun part begins: Packaging the whole thing.

MAGIC!!!!

So there’s no soda bottle big enough in this world (please prove me wrong) to swallow up 5 cell wide rows. The \m/etalpaxXx required a 3-liter soda bottle, and they were only 4-parallel groups. And while I could have planned ahead and ordered wide heatshrink tubing, that just doesn’t work with how I like to build these things – i.e. right now.

I did, however, buy a six inch wide roll of Kapton (Crapton, since it was from a Chinese ebay seller, and doubtlessly not real DuPont polyimide film) for Make-A-Bot’s future build surface. So I decided to just give it a try with finishing the packs up. With some cut up sheets of adhesive-backed foam rubber fitted on the cells for shock isolation, I wrapped the Giant Crapton around the whole pack several times in two separate loops. I think it came out great. The tape doesn’t really stretch, so it doesn’t look as “heat-shrinky”, and I wouldn’t say it’s waterproof. But it got the job done.

After a brief interlude to reconnect six little wires, Segfault is now once again attempting to kill innocent riders.