A wonderful weekend of work kicks off with major progress on Ãœberclocker and a bit of work on LOLriokart!

More to come after I wake up at 3PM today…

Übercløcker

The first order of business was to construct the back end of the bot, which acts as the alignment device and reference plane for the entire rest of the bot.

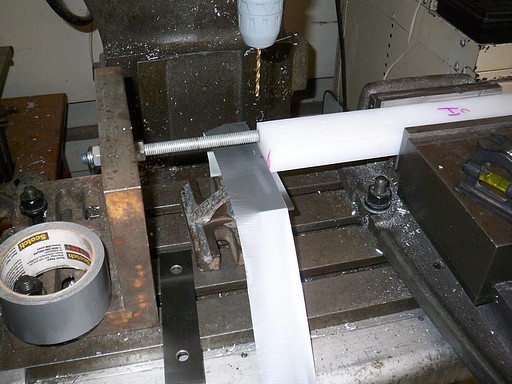

This was a bit of tricky business, since the piece of UHMW is 20 inches long. The Bridgeport mill has…. 20 inches of table travel. A bit problematic. And I only had one non-dysfunctional vise (The other one, shown on the right, is a cast iron Swiss cheese sculpture)

The partstopping angle plate came in handy this time, since it allowed me to shift the UHMW bar left and right to known locations so I didn’t have to edgefind every single time I needed to perform an operation on a section out of reach.

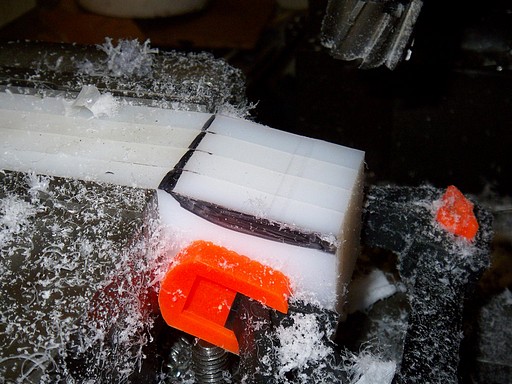

In this episode of Improper Machining Techniques 101, how not to support overhanging work pieces! This is a machine parallel duct taped to a smaller angle plate duct taped to the table, all shoved under the section of UHMW.

This was too sketchy even for me, and so I ended up switching to some of those step clamp blocks. The duct tape couldn’t hold the vibrations of milling slots.

About this time, the Y-axis readout started funking out, losing its value every few passes. This caused a headache really quickly, so I dismantled the slide to find out if something was loose or not.

…. I’m not sure if this is how it’s supposed to be wired, but obviously it’s beyond my level of knowledge. I secured the cable to a similar level of build quality (zip ties!) and tightened the mounting screws (which were loose – likely the source of the issue) and the hiccups stopped.

After some more fiddling with working on a 20 inch part in a 20 inch workspace, here is the completed back rail (without countersunk holes yet). The piece is actually not straight due to UHMW’s tendency to warp while machining (and its naturally warped state). It has a roughly .020″ bow over the longest dimension, which means one side is slightly shorter than the other.

The critical dimensions don’t depend on the actual part height, so it’s not a loss.

Next up were the side rails. To save time and sanity, I set up the angle block as a partstop and clamped all the rails together to be processed (at least, drilled) as one piece.

I decided that this was going a bit too far, since 2 inches of material is alot to ask of any drill bit and totally out of reach of the smaller bits. So I split the rails into left and right sides and proceeded with a setup similar to the picture.

Midway into Saturday evening. All four side rails are processed with the major features (no countersinking or slots, which will come later), so it was time to arrange a test fit & sanity check.

This also included fitting the spring-loaded front support legs and testing them out. Verdict: Pass, but final testing is required. If I ran my calculations correctly, the bot should move over the 1/4-3/8″ floor hazards at Robot Battles with ease, and should balance 30 pounds on the end of the clampfr0k with the springs at full deflection.

I actually managed to lose the other spring, so I’m ordering a handful from McMaster.

After some more hours of work making matching axles and spacers for the newly created left side, it was time for another episode of Pretend-o-bot.

This episode of Pretend-o-bot shows the milled sides and back rail, with the two existing wheels fully mounted and the front supports (mostly) in position. The final bot is taking shape very well. What’s not shown is the almost mirror-like finish of 1500 grit sandpaper on the axle spacers. After all, I can’t photograph through wheels.

I expect some assembly of the frame parts today. Now I’m only waiting on another shot at the waterjet cutter (which may or may not still be mad at me)

Ground clearance check. Chassis: 7/16″ (with baseplate). Front supports: 3/16″. The bottom of the supports might be beveled inwards to allow traversing of the floor hazards.

This is another one of those DUI (Designing Under the Influence, usually of -3 hours of sleep) aspects of the build… why on earth did I make the forks stick out for their entire profile as opposed to only the tip?

What’s left on Ãœberclocker? A bunch of things. All the side rails need their slots and other features to mount the motor. I need to build two more “inner-inner” pieces to hold the back ends of the motors. All countersunk holes need countersinking. The fr0k needs workable parts and final assembly. The fr0k drive needs to be built (actually, it needs to be completely designed first!). I need to make a few more little widgets. Then everything needs assembling.

That’s just the mechanicals.

LOLriokart

Work on LOLriokart Friday evening was focused on overcoming the steering and brake issue. I’m proud (can I really be proud of such an abomination?) to say that this has been solved, so work can shift to the back end to hook up the drivetrain goodies.

Here’s an overview of the progress.

I now have the other half of the steering joint. The assembly is rather simple – a large steel bolt retained by an aluminum block, which has a crossdrilled hole to fit over the steering kingpin.

The additional holes on the front of the pivot block are to mount the actual steering linkages when I get to them.

This is the pivot assembly. The aluminum block has a 1/2″ ID bushing on the top and bottom, and a big 1/2″ cap screw with the head cut off is mounted in a hole. This cap screw will be the front axle stubs, and both the brake and wheel/tire will mount on this.

The cap screw shaft has a big flat machined onto it that is captured by two 1/4″-20 screws. Yes, I’m holding the axle on with set screws.

Famous last words, or a potential Loctite sponsorship?

Wheel mounted for a test fit. These cheap handcart wheels have no internal bearing spacer, unlike roller skate and scooter wheels, so the compression force provided by the axle nuts has to be just right or it will seize. Or wobble. I will probably make an internal spacer to save the trouble.

Front view, showing a profile of the assembly. The Brake-O-Hubâ„¢ extends into the band brake. The brake body itself simply slides over the 1/2″ axle stub, and the arm that sticks out the top will be retained by a bracket to the pivot block. This is why the block has those two little holes on the top surface.

A little spacer keeps the Brake-O-Hubâ„¢ the correct distance from the brake assembly when the axle nuts are tightened.

And in a slightly serendipitous moment, I find that I actually do have an assload of steering travel. I think this is about 35 degrees, and that’s on the more restrained (due to the shape of the cart bottom) side. Looks like the steering arms are going to be pretty long to take advantage of it.

That’s it for now… Work this weekend will probably be concentrated on Ãœberclocker instead of LOLriokart, since I do want to extend my life as long as I can.

Bot on?!