In this part, I’m moving on from the aluminum parts of the bot and putting in some REAL STEEL. First order of business is designing the front armor, the angled pontoons for which Overhaul 1 was somewhat famous for. Next, I’ll put in the lifting forks, and finally the Razer upper clamp arm which is supposed to Razer come down on opponents and mercilessly crush them like Raz… hey, wait a minute.

Welcome to the Overhaul 2 Design & Build series, episode 4: A New Work Plane. Because that’s what’s going on here. So many work planes

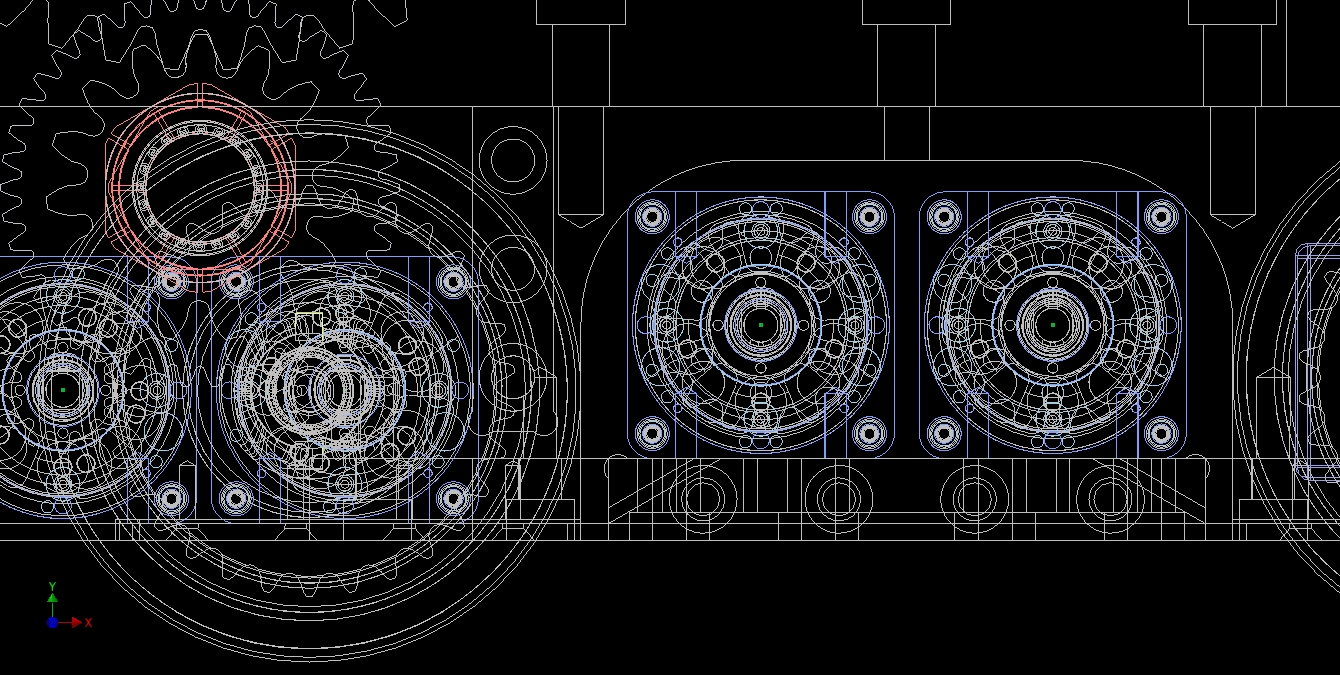

The work planes are where sketches are drawn to make the solid pieces. While Inventor will let you sketch directly on the surface of a part in an assembly, I wanted to keep this part a little more separate from the assembly. Therefore, these work planes are defined from the assembly parts, but will still be around if I delete the part (e.g. to replace it with a new version), or edit/delete a frame part.

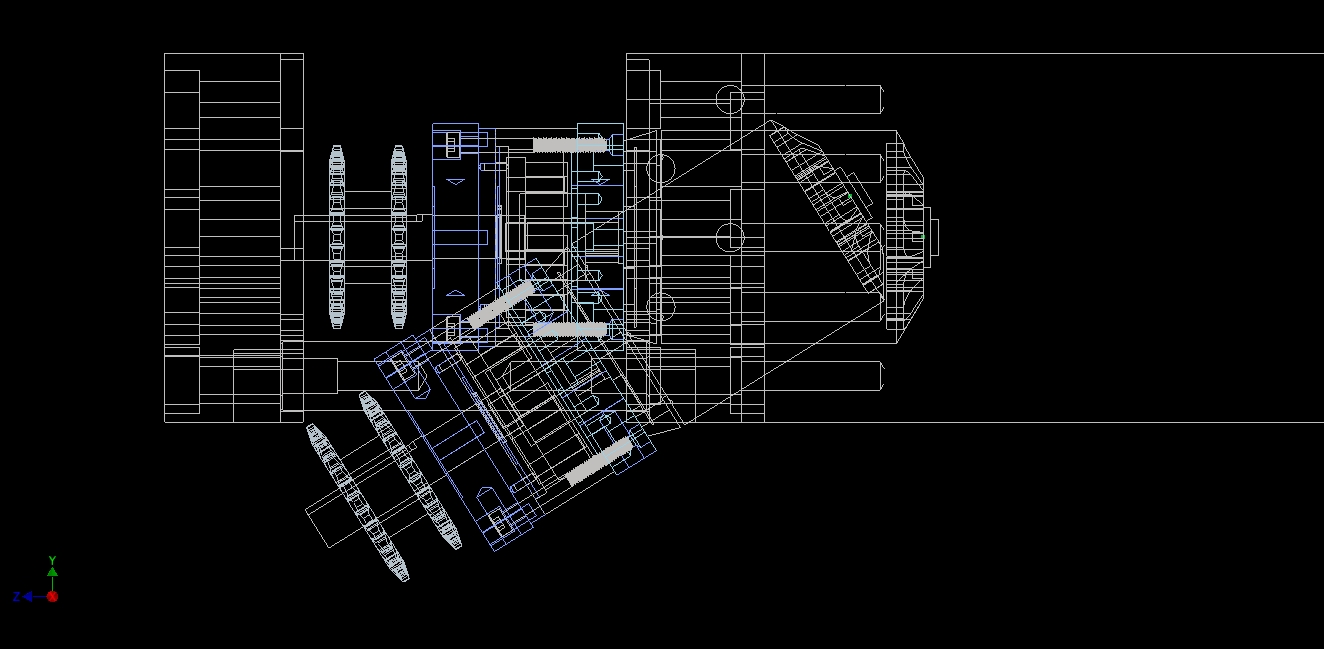

I honestly didn’t know what I was aiming for when I started. I knew the general shape of things from the sketch model, so I just started making a basic wireframe. The best term I could probably use to describe these first few versions of the pontoons was “Gundam armor”. Impractically faceted and pointy, and likely very hard to make in real life.

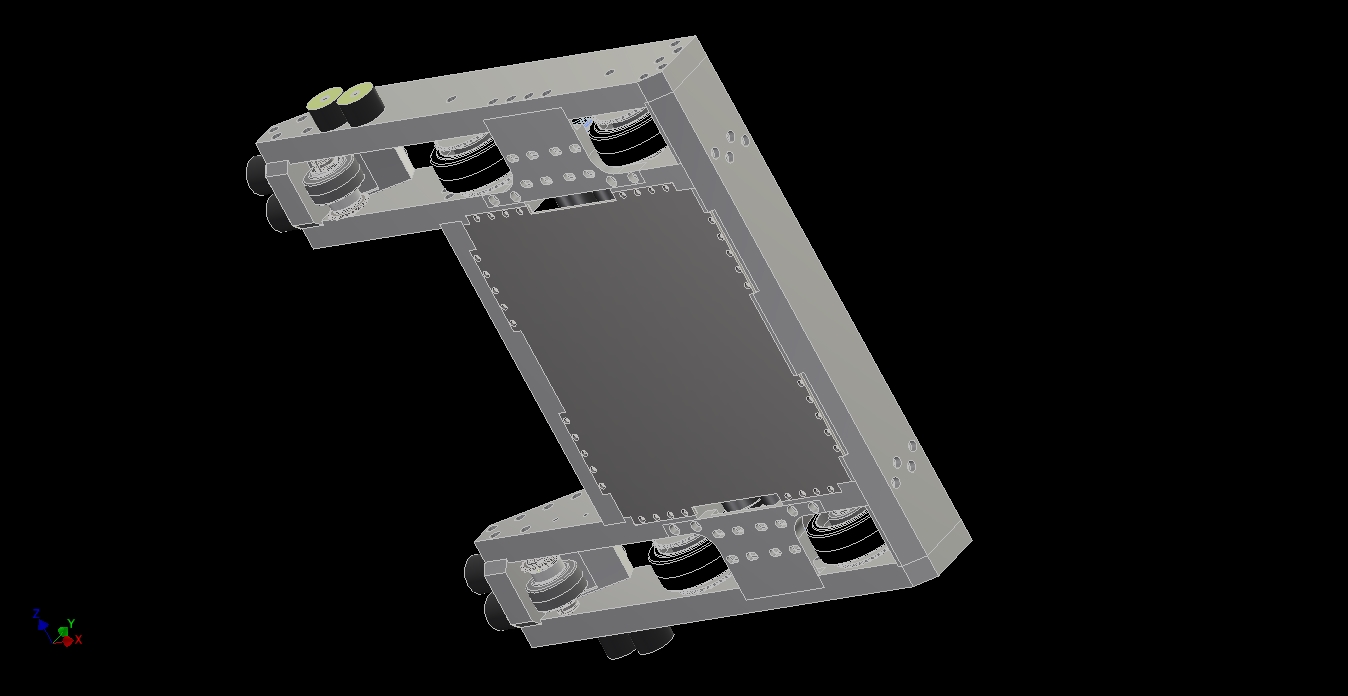

Here’s one completed example. I wanted too many things out of one design – the flat sides for easy attachment to the shock mounts, the sloped outsides to deflect KE weapon blows, and the sloped upper panel to protect the liftgear and better act as a w*dge passive-traction-leverage-implement. (It’s no longer polite to say w*dge in BattleBots!)

That’s how many work planes I got up before I decided to just start over. This was the accumulation of 3 revisions, so it included a lot of angles and facets I ended up ditching.

Here we are, after tossing THAT part in the dumpster of bytes. This shape more approximates the original sketch, with its sloped sides and double-angle front. I initially did not pursue this because I was thinking that modeling the non-straight sides would be a pain. To generate the surfaces, I use the wireframe (made of many sketches on different planes) to generate boundary surfaces in Inventor.

The double-angle front armor was borne of some musing about how to overcome horizontal spinning weapons. You can usually do only two things with big KE weapons – absorb them, or deflect them. The former usually ends quite badly.

We saw in the Bite Force vs. Tombstone final how effective usage of material geometry can bounce KE weapons around, since no matter how much energy you pack in a weapon, your bot still only weighs 250 pounds. The idea of the double-angle pontoons is similar to that of a Jersey barrier, which is designed to bounce wayward cars back towards the correct side of the road. The lower angle slope guides the weapon upwards, and then the sudden higher angle slope destabilizes the now elevated weapon. The height of the angle change is set just barely above the average blade height of all the big hitters at BB season 1*

Adding to this deflective geometry is the soft rubber mounting points, which on a good connect will squash and cause the pontoon to come into contact with the ground. The hope is that this will basically mean the opponent suddenly reacts against the arena floor, adding to the bounce effect.

That’s the theory – we’ll see how it works in practice. But the effectiveness of even a single angle, solidly mounted deflective plow can be seen in the snippets of Captain Shrederator vs. Stinger (trust me, it was even more awesome in person) as well as the Bite Force final.

*The sound you hear is everyone rushing to build variable height weapons

Adding more of “the details” to the pontoons – now they have vertical panels and bottom plates. These are all still surfaces. The plan is to use this part made of surfaces as a reference to “grow” the final plate models from.

For now, I left this surface as-is since at the least I’ve defined the shape of the pontoons and therefore the shape of the front of the robot. I moved onto the next Most Critical Module, which was the lifting arm assembly.

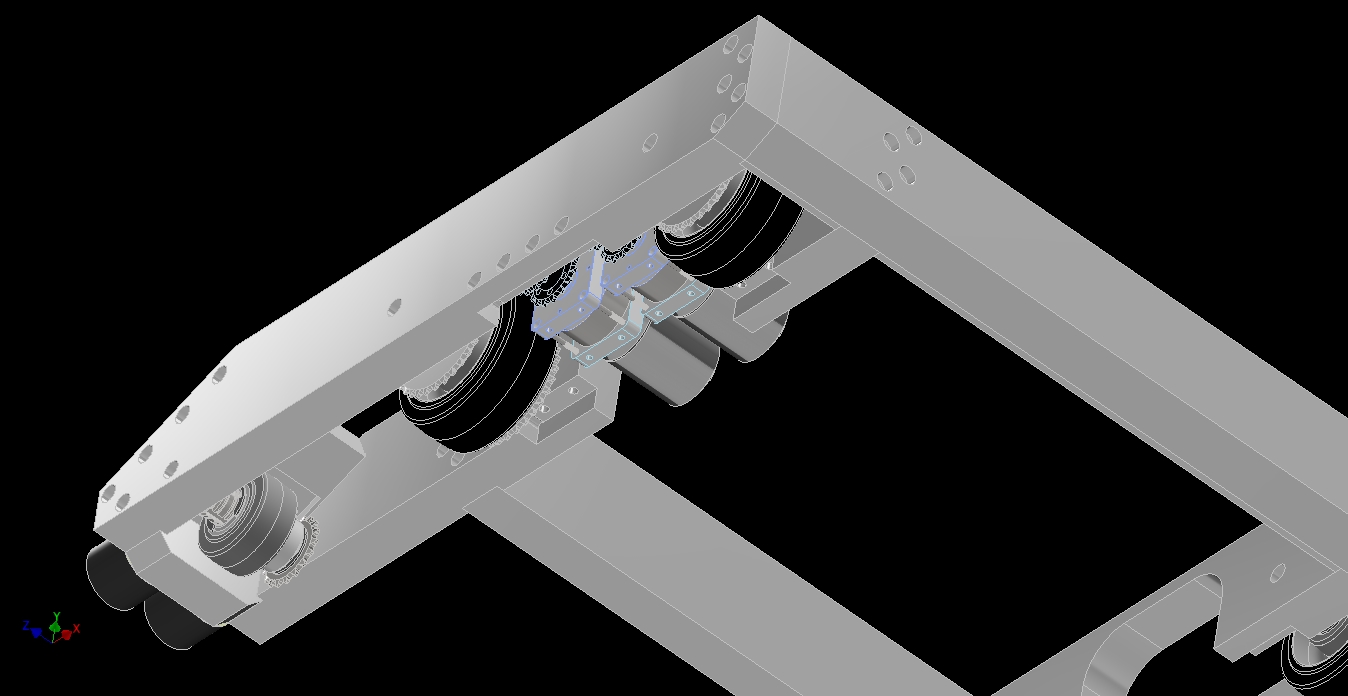

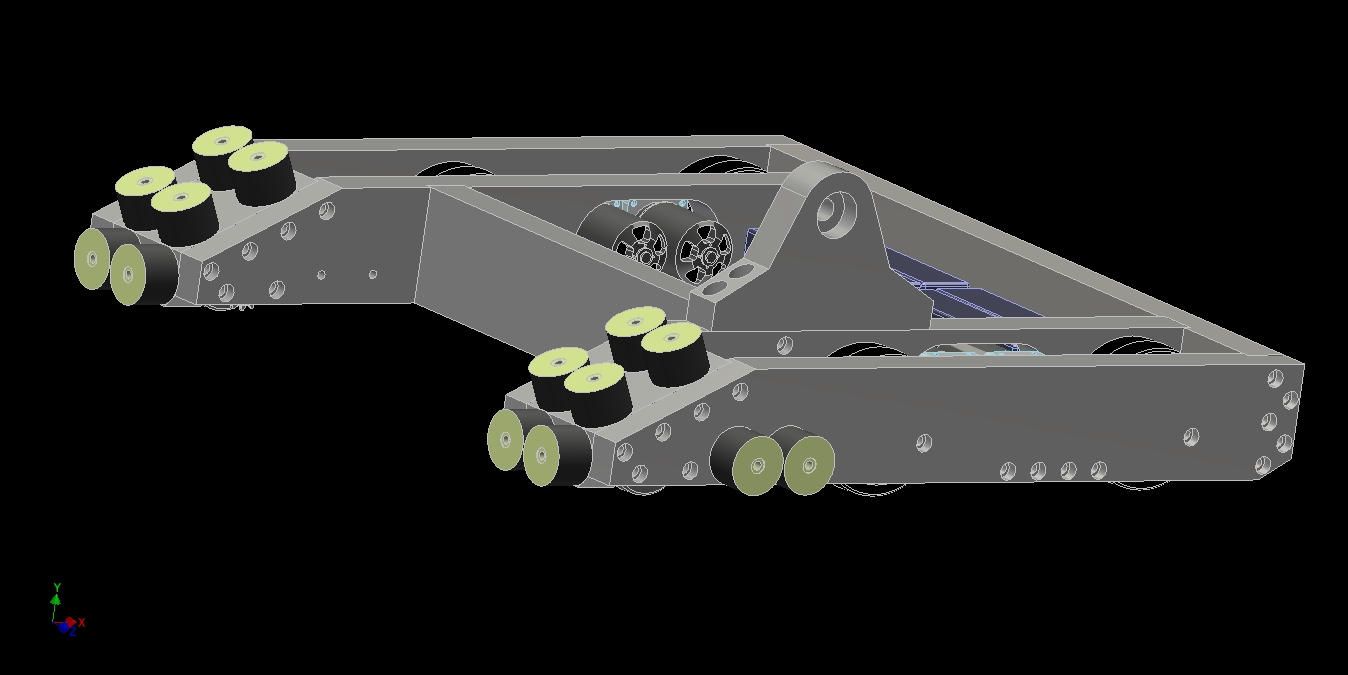

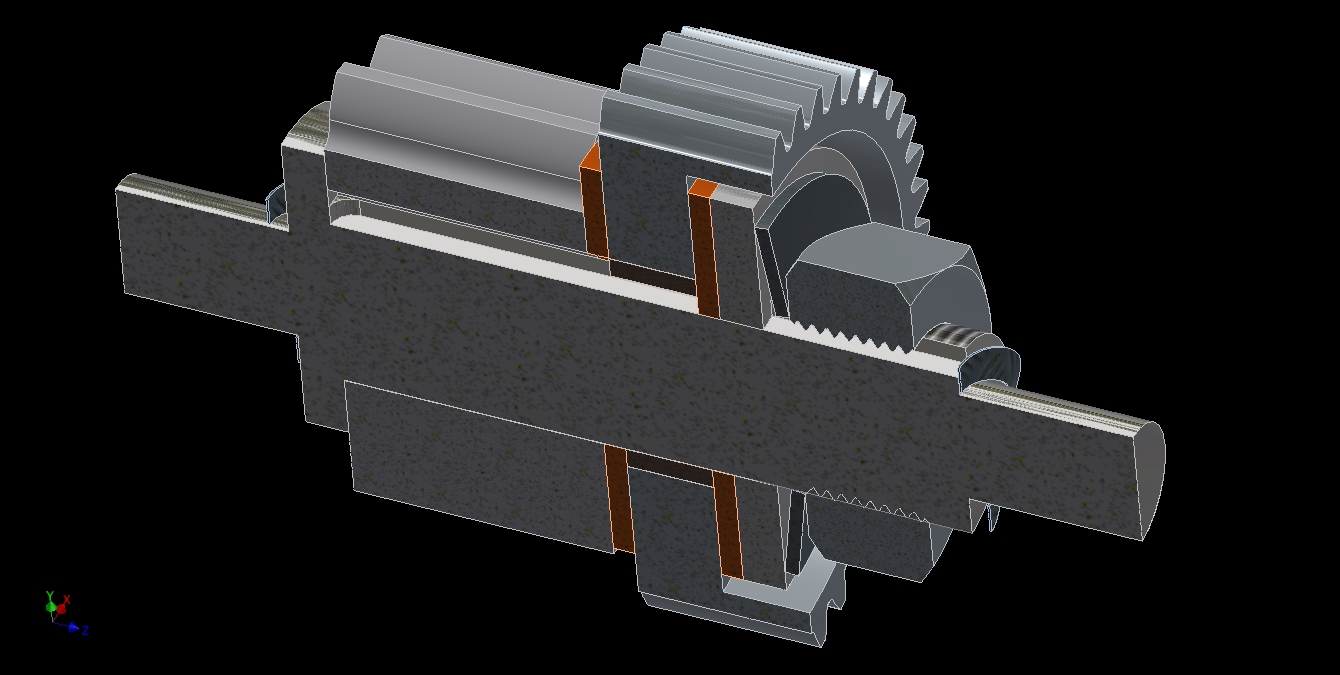

I burped this out after a few hours of thinking about how best to attach the forks. Fundamentally, it’s a big center hub with an ear attached to it where the lift actuator will eventually mount – dimensions and spacings for this were guessed, since I hadn’t designed that yet and wanted to keep it flexible. A similar structure appears on Uberclocker Remix on its main lift shaft.

For OH2, I wanted the forks to be easily removable in the event of oh god I got owned but somehow won. To do this, the fork arms can’t be made a permanent part of something, and the attachment method also needed to be rigid in bending as well as be able to handle what might end up being thousands of ft-lb of torque if I actually use the full crush force on something.

I decided on a dead shaft system where the fork arms also have bearings (rather, just bushings) in them with the hub a separate piece. Eight 3/8″ threaded studs are anchored into the hub, and the forks are retained by 8 nuts once they are slid onto the hub. The way to quickly remove the forks would be to remove the lift shaft (two bolts), then undo 8 nuts per side, and then slide them out.

The lift hub is therefore a totally indepedent structure, so I could conceivably run OH2 even without arms or without the clamp for some reason.

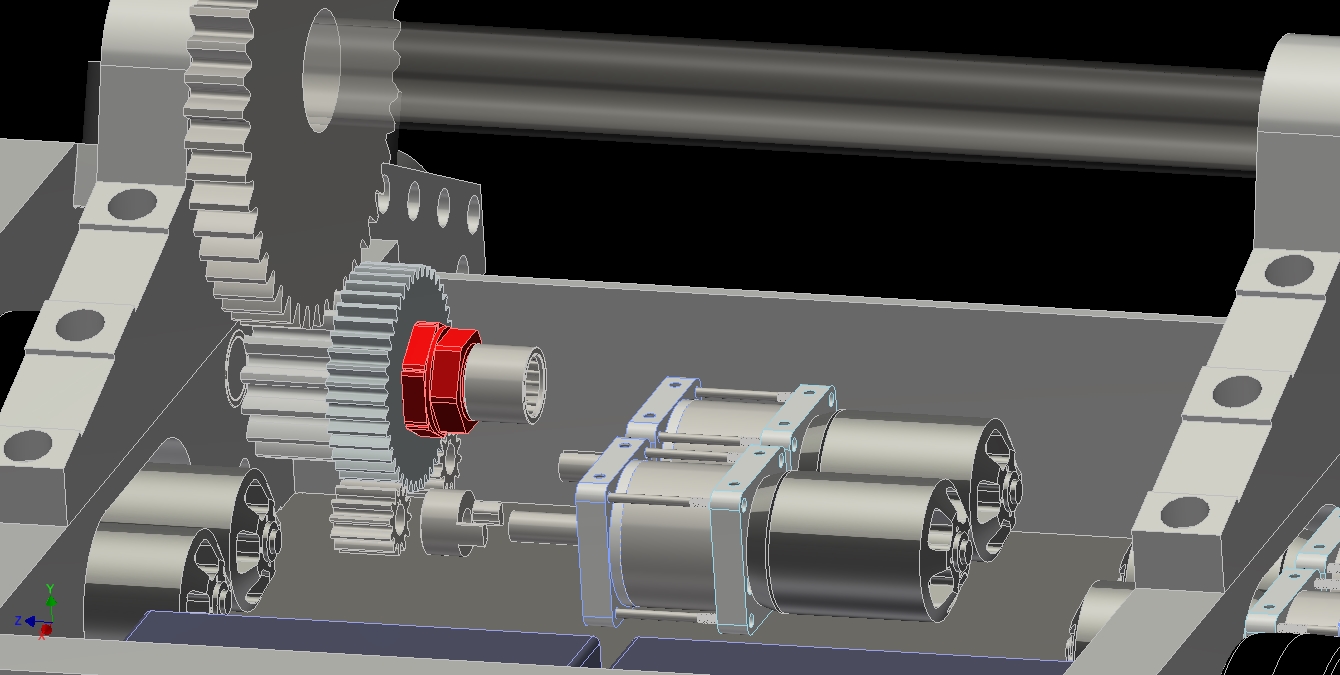

Because this thing will be reacting all of the clamp actuator force through itself, I decided to check in on how the material was going to handle it. Having a 5″ round wad of solid aluminum in the center is great, but not for weight. I wanted to see how far I could hollow it out while retaining rigidity, so it was back to the good ol’ FEA tool.

If you haven’t ever seen FEA before, it basically does all of the stupid bending-twisting-beam calcualtions you had to do in engineering school by hand with a stupid lookup table (IF YOU’RE LUCKY AND HAVE A VERY GENEROUS PROFESSOR), on very finely subdivided elements of the part such that the result is a model of how a very complex geometry reacts to forces and deforms, broken down into simple numerical problems for the computer to crunch through quickly. Quicker than you. No, I’m not bitter about my Mechanical Engineering degree or my classes at all. Why would you even THINK that????

In a typical FEA simulation, you set the constraints (how the part can’t move), set the loads, the materials, and any contact conditions (e.g. between 2 parts, between 2 materials), and let the computer have at it. There’s many ways to do FEA WRONG that I won’t get into detail here.

Here, I’m doing a bending force analysis on the point where the clamp actuator mounts. I wanted to see if this would cause problems with the whole thing deflecting when OH2 mashes down with a few thousand pounds of force. The conclusion is that no, this hub is fine. Double shear for the win!

I usually design to Yield Strength for materials (the point which a material bends). It’s more common to design to Ultimate Tensile Strength – the point when the material breaks. I prefer Yield because if something bends in battle, you’re hosed, but this won’t put any planes in the air…

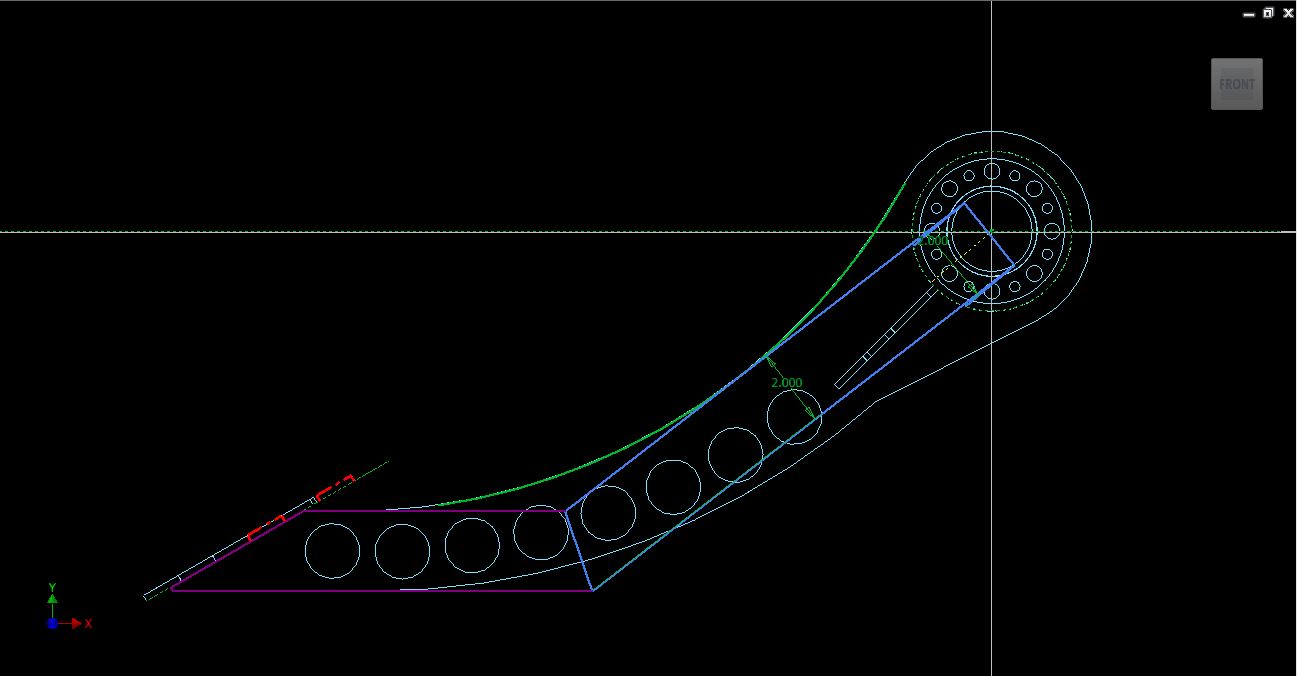

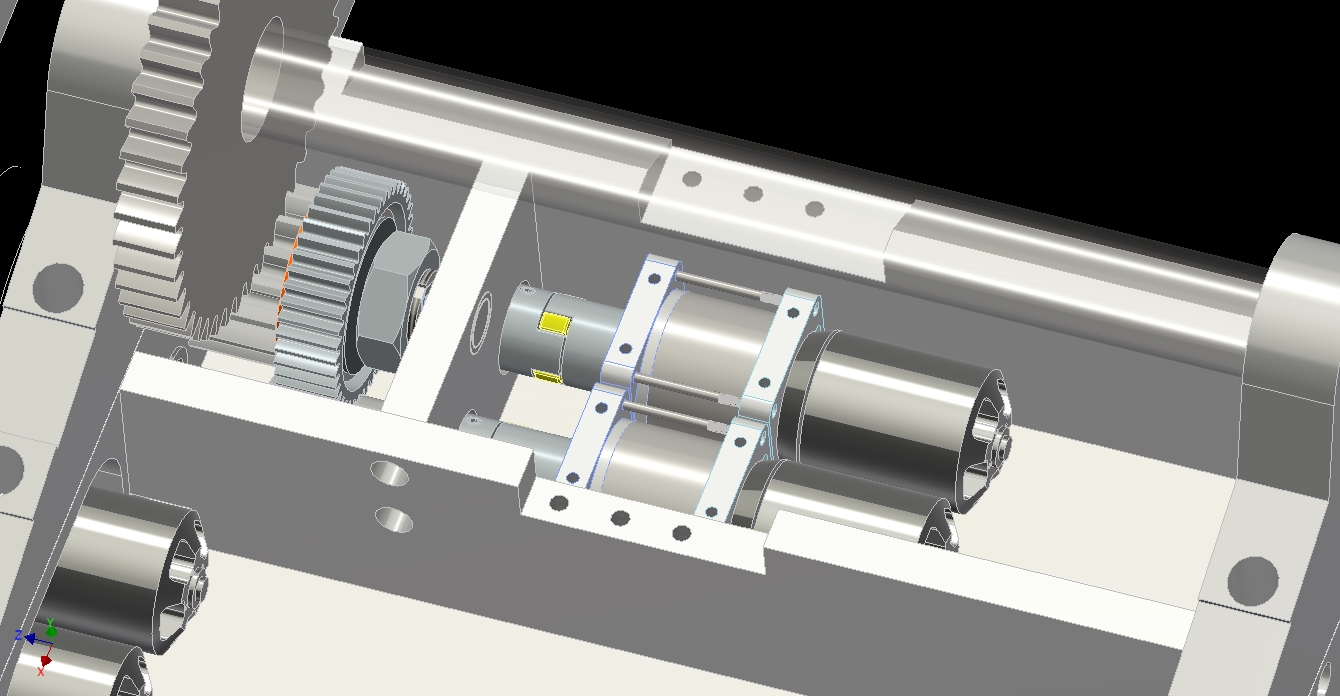

Having run through the hub once, I started generating the lifting forks. They’re going to be made from some steel tube and some steel plate, cut out into scientific shapes and joined in less than scientific ways by yours truly.

At this point, I was still interested in curved forks. I wasn’t quite sure how I was going to make these yet, but hey, why not try CADing something different? The tube profile was generated with a Sweep of the square tube profile (modeled without fillets).

Now in solid form…

I did something slightly nontraditional here, and made each of those elements you see – the tube, the tube caps, the fork curved square tube, etc. a separate solid body in one single Part file. This let me easily reference the parts off each other. To break this down into things I can cut, I highlight and save each solid body individually.

Modeling the “fish hooks” at the end from what will be waterjet-cut steel plates.

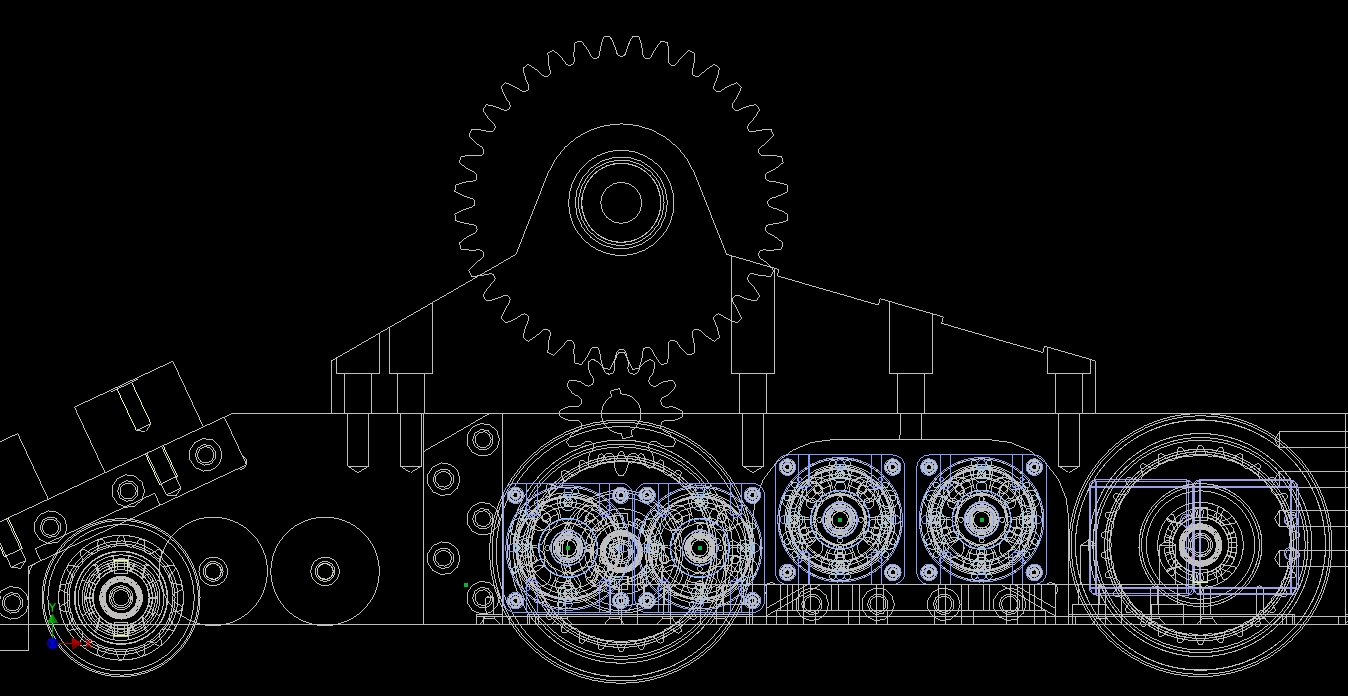

Time to see if this fork can stand up to the maximum force exerted by the upper clamp arm. This is a view of the “finite elements” in “finite element analysis” – the computer solves iteratively how each of those little triangular sides deform based on some relatively simple continuum mechanics rules. I modeled for 2500 pounds-force per side, at the tips. This is basically the full, err, bite force of the upper clamp arm (ideally each fork seeing 1/2 of the load).

First attempt: Dorky mild steel tubing.

Nope. Utter failure. Everywhere.

Second attempt: 4130 steel, normalized (not heat treated). This was assuming I could get 4130 in those needed sizes, which later proved to be a problem. This is “edgy” – the yellow on substantial parts of the tube means that on overload conditions like mashing someone into the wall, it could bend and fail there.

Okay, how about using geometry instead of more hardcore alloys? I modeled a single rib that runs the length of the fork arm on the inside. This is not preferable at all, since I don’t want to have something sticking up right where weapons can reach it, but I was interested in how it changes things.

The rib option is workable. This result is a little deceiving, since I had the force concentrated on a small region of the material (the hook), so it will deflect more than everything else. Really what I’m paying attention to is the green-yelow on the rib itself and the tube being largely blue – the rib has transferred most of the stress out to itself, which is what is expected.

The bolt holes are still a little concerning. They are, however in regions which will be tightly bound next to other parts, which simple FEA modeling doesn’t capture.

Instead of the rib, what if I just went to a thicker steel section? Here’s 1/4″ wall tubing (still using 4130 – not even sure if it existed at this point!). The performance is better than the 1/8″ tube version without the rib, but actually not too much. Since the rib is further away from the imaginary axis which this arm would bend along, it can resist the forces far better than more steel closer to the axis. Geometry!

I stuck with this for now, for the purposes of moving on. All of this analysis was really completed in one evening, by the way, so this wasn’t days and days of running simulations. I was willing to trade the inability to use all of the upper clamp force for some “easy” – roll a tube, weld some plates on, whatever.

I’m going to skip ahead a few weeks here, since I like the continuity of this thread about the forks. You’ll get to see the “final” fork design, even if the photos of OH2 from here until a few posts more will be showing this “old” design. Basically, after finishing the bot in whole, I began revisiting parts which I felt I had left “sketchy”, including the forks. In the intervening weeks, I had called around getting quotes and prices for sourcing the arm tube. I had thought I had a handle on sourcing 2″ square 4130 tubing, but I was either imagining it or they changed the Matrix between the design and my revisit.

Bottom line was that I thought using 4130 was no longer realistic in the (Time * Frustration) factor department. Therefore, I decided to capitalize on known available materials, and good geometry.

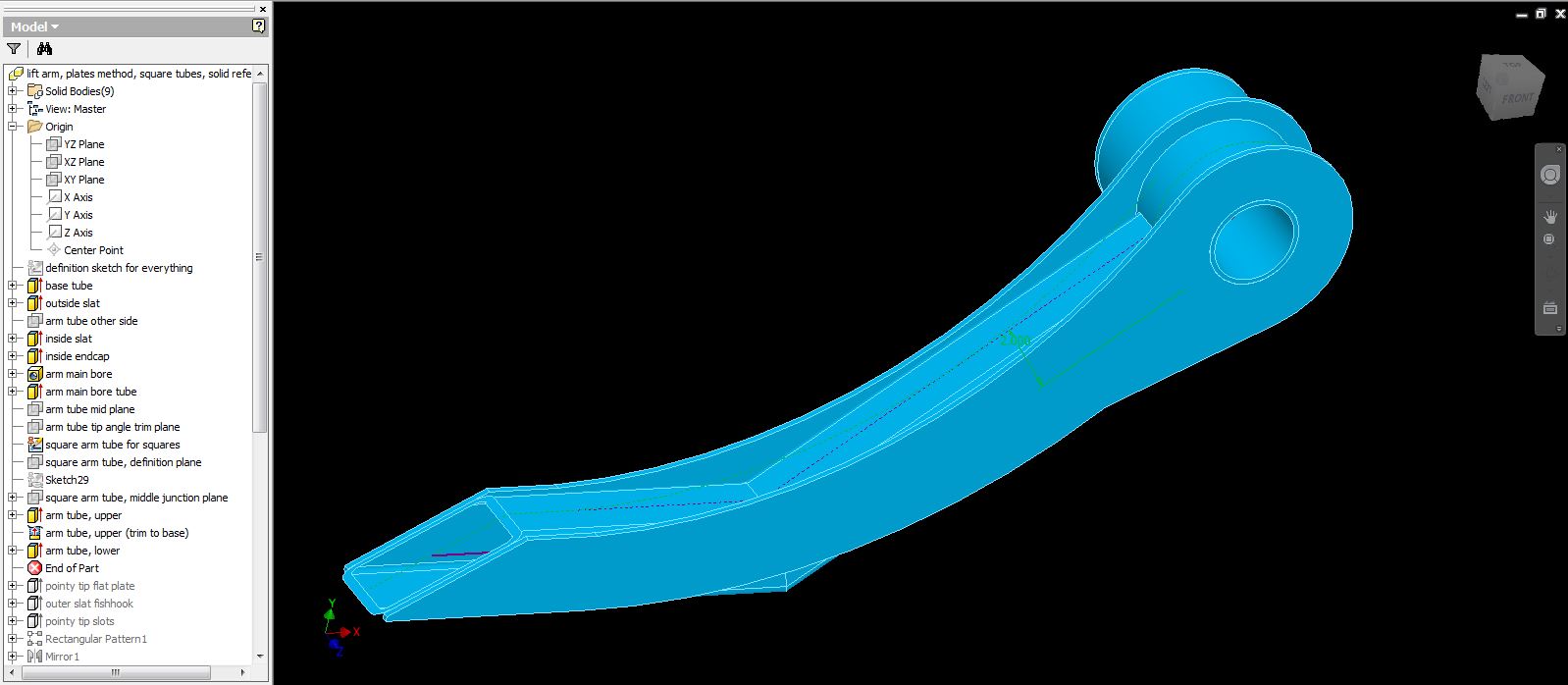

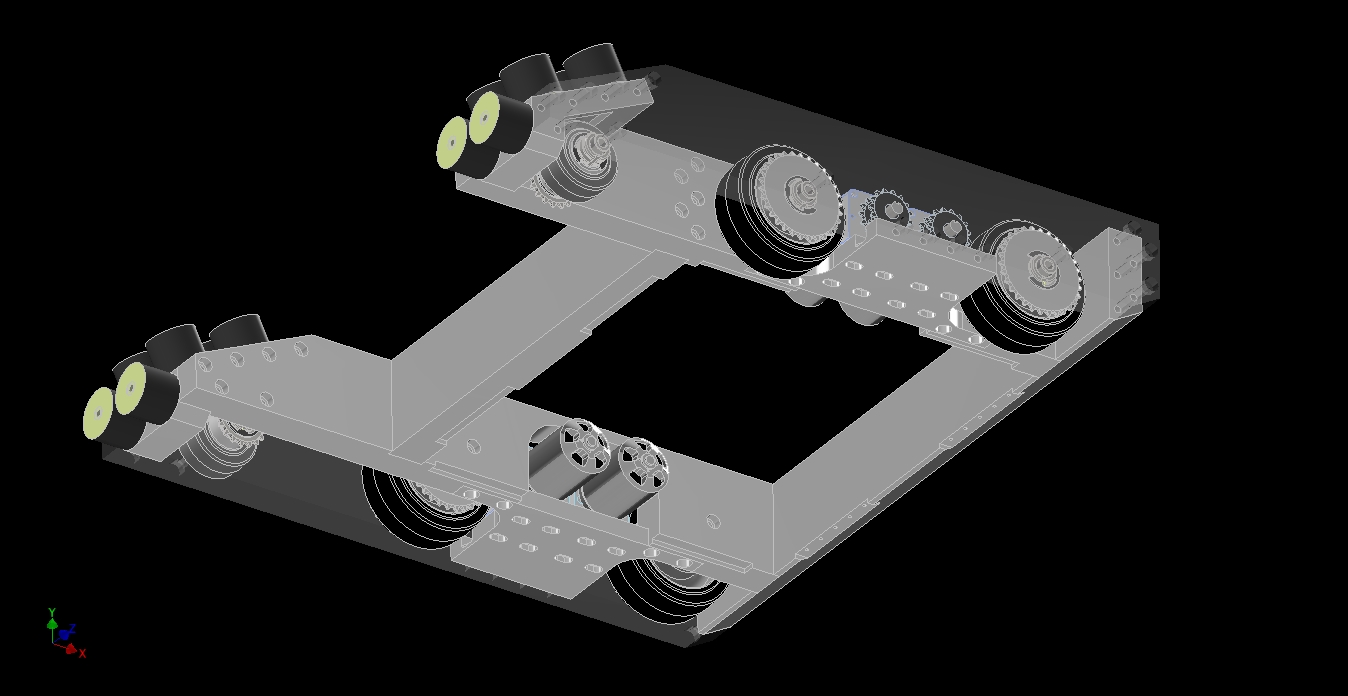

This time, I’m using a “tube and side plates” approach where the side plates define the shape of the arm and also carry the majority of the weight. The tube really is there for closing off the top and bottom surfaces (sideways rigidity) at this point, and I could even replace it with a rolled curved plate and have an H-profile beam.

This design kind of looks like the original “rib” design, except the ribs are sort of discretized into the new side plates.

The plan was to cut them from the same material as I was making the upper clamp – AR400 plate.

AR is my new favorite material after building OH1. It’s just so good and versatile, and is my mental go-to if I need a ~140ksi yield strength material that can remain mostly flat. Usually, stuff with that high tensile strength isn’t easily welded, but they designed this alloy specifically for tacking Iron Man suits together in the oilfields with tin cans as filler material or something, so it’s also easily weldable. You do lose some strength in the weld area, but again – geometry can help overcome, or at least offset that.

Throwing it into the FEA module. I modified the location of the force so it wasn’t causing signficant deflection of a single point (the hook) – instead, it’s centered on the large planar face.

Some geometric changes and lightening holes later, and this is the curved arm design. The holes in the side lost about 2 pounds without substantially raising the stress levels.

The geometry here is modeled as “bonded”, meaning no movement at material boundaries is permitted. Clearly this isn’t true in real life – to approximate it, I’d have to weld substantial portions of the holes to the arm tube, or the movement will cause one or the other part to exerience more stress than designed. FEA is one of those things which is tobe melded into everything other aspect of a design, not the end-all answer to a problem.

Skipping forward again another week or two, I was discovering that the tube rolling process was going to be problematic. First, the sides won’t be flat any more – the tube will bow out. Second, there was no tube roller nearby that could handle the material – not in my network, anyhoo. To get the tubes rolled by a known bot-friendly company would have been 2 weeks of leadtime since they were on the west coast.

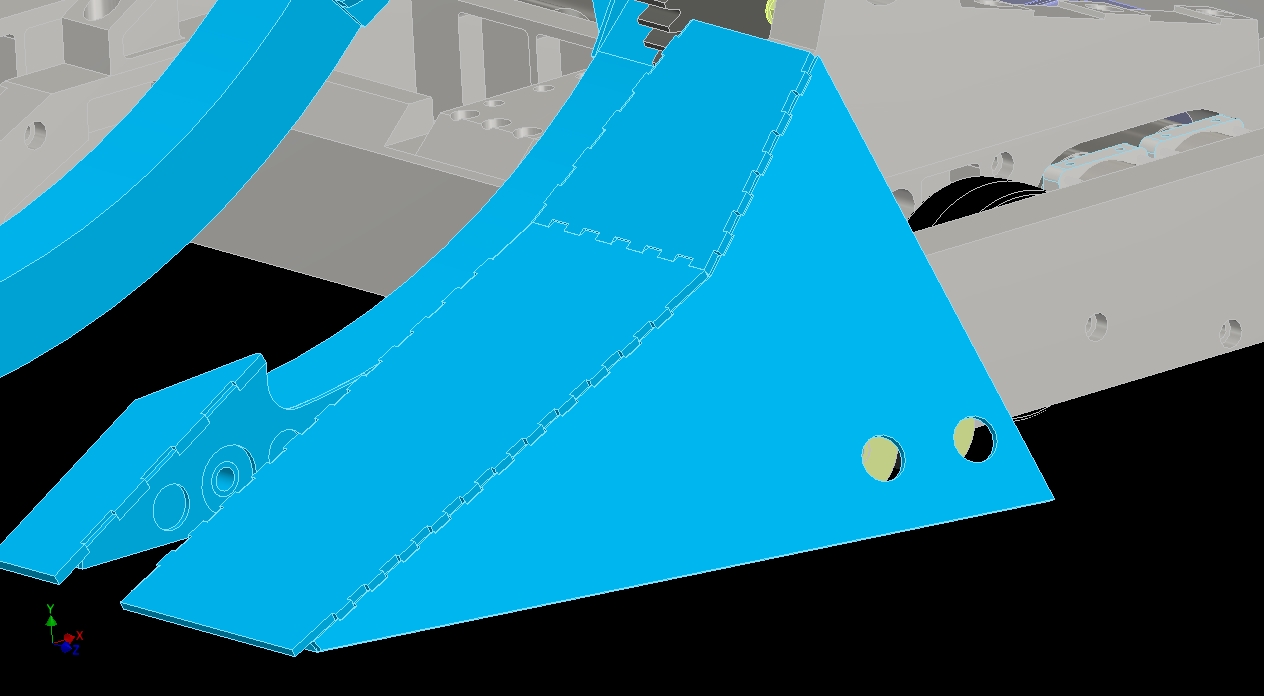

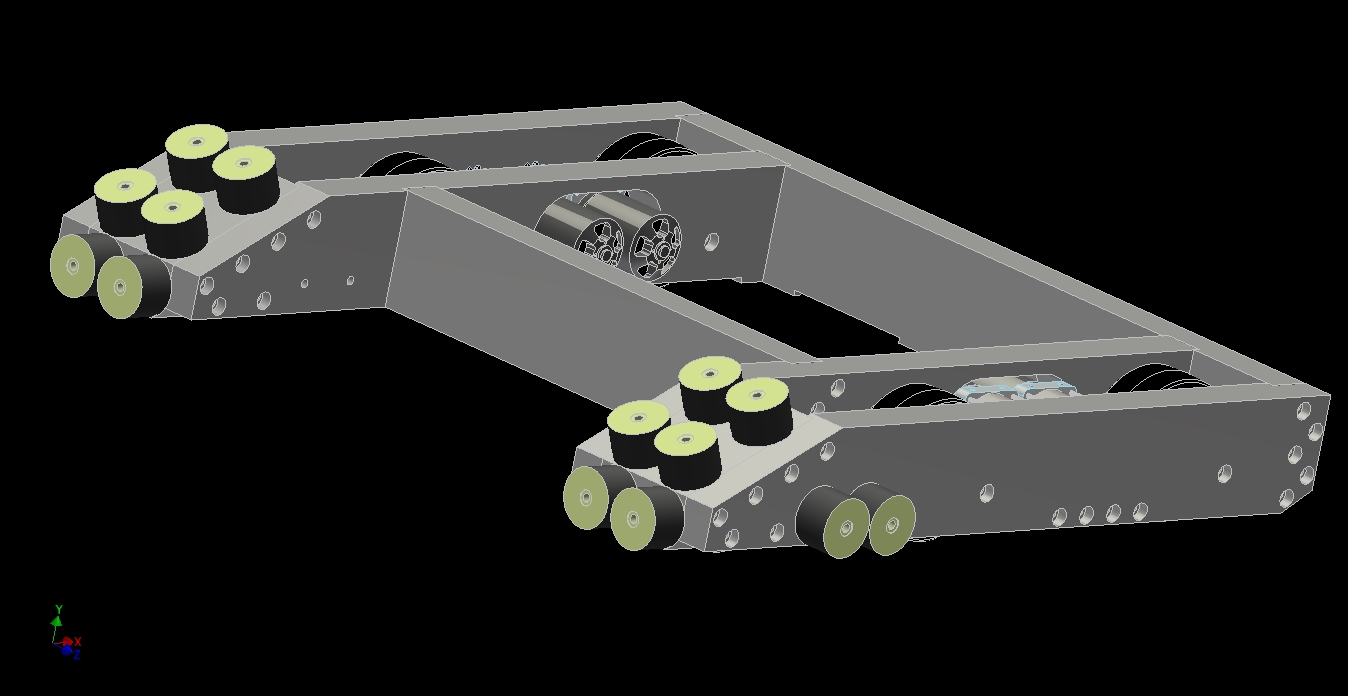

So I decided to do the final refactor of the design into something which can be built right now with materials and methods on-hand. This means angles.

The “look” of OH2 had been defined by the curved forks, so I wanted to keep an element of them in the final design while hiding the square tubes. Conveniently, the curved side slats are also excellent gussets. The idea was to approximate the curve as best as I could with regular square 2″ tubing.

The above shape with the “elbow” of square tube sticking out underneath…

…which I hid with an “inverse fish hook” coming from the side slats. Hey, they look intentional now!

Looking at the analysis of this part, the problem areas are where I’d expect them – the areas of the side slats near the elbow primarily. (After this picture, I increased the fillet radii substantially and the narrow neck near the elbow was no longer an issue)

As I had modeled these new AR400 plates with anticipated cutting tolerances, there’s gaps in them which I could not force to be “bonded” contact. As a result, you can see the corners of the front angled plate being “highly stressed” – causing the safety factor minimum to be artificially low in that region. In real life, these are going to be welded securely.

Alright, time to undo the timeskip (this was “roughly week of 3/7”). Now we return to the pontoons and upper clamp arm.

I took the surface reference model for the pontoons and literally grew those surfaces into 3/16″ plates…

…and then did my usual “edge stiching” finger joint method on the individual plates. This will make the part very easy to self-fixture for welding.

More details, such as internal gussets, have been added to the pontoons, with more to come.

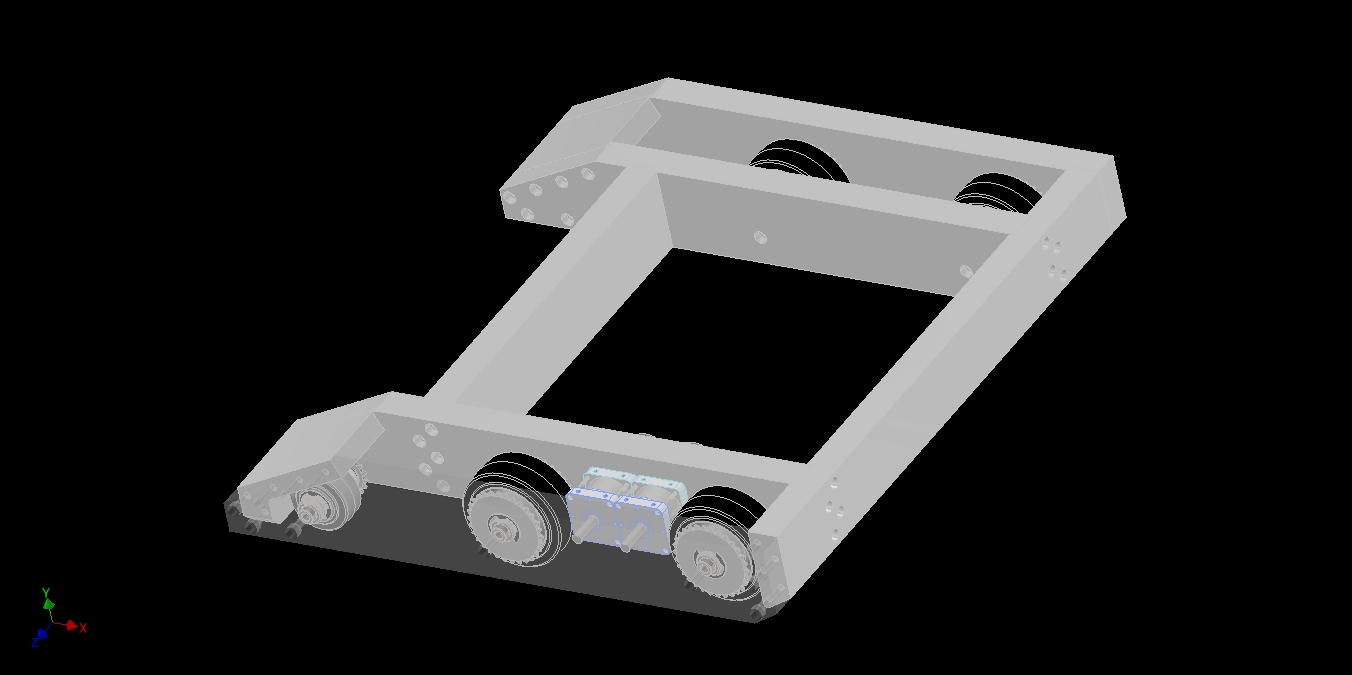

With the front pontoons done, I brought in some more components as a bit of “work-ahead” – thinking about the next step while I’m working on the current one. I knew what I had to do for the upper clamp arm, so I just had to crank it out while thinking about electronics mounting, the bane of mechanically-minded robot builders everywhere. Can I just cast the whole thing in hot glue and be done with it?

Coming up next: The upper clamp arm geometry and actuator!