And now, back to your regularly scheduled content!

I determined that the next location to practice my back-alley bodywork skills on Mikuvan was Oops! I mean, we interrupt this weekly installment of Big Chuck’s Automotive Blog to bring you ROBOTS!

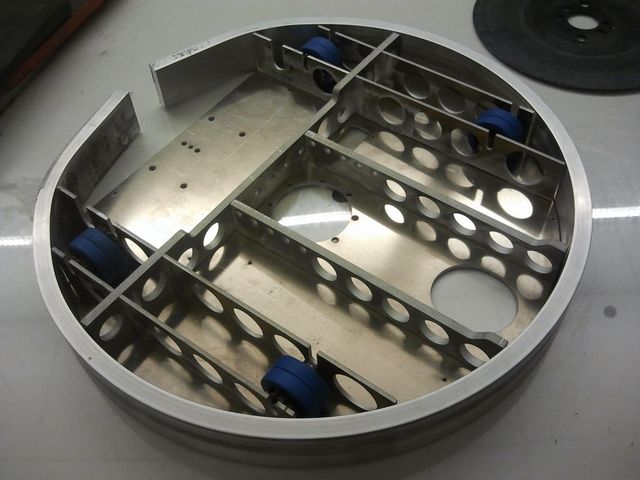

It’s been a while since the last Candy Paint post, and tons of work have been finished, but there is still a majority to go. I’ve finished most of the small parts and machined assemblies that will go on the bot, but the frame is not yet welded. I hired out the frame welding to my associate Jack at the D-Lab space down the hallway; since I determined that trying to learn aluminum welding and make a critical weld at the same time is best avoided, especially if I don’t get to arbitrarily remake the parts if I mess them up. The flip side is that I may only have the frame in hand by this coming weekend

Which is one week from Motorama. Uh oh.

In the mean time, let’s start with some machining. Rather, the product of someone else’s machining (boy are we off to a good start):

This is the main blade pulley for Candy Paint, sourced from a shady Chinese shop via mfg.com.

Alright, it’s not fair for me to call them ALL shady, since if you can machine a part to a customer’s specified requirements and tolerances, then there’s no arguing really. Here’s some hard data for the curious. I ordered this part in quantity 4 to sweeten up the deal very slightly over a one-off. The cost was $25 per part, single piece machined 6061-T6 aluminum. There was an engineering fee/setup fee of $40 and the shipping came out to $80 because I had asked for an express air service since I needed them quickly.

All up, about $220 for FOUR of these jobbies. These are hard numbers for your amusement, if you choose to have robots machined by proxy. As far as I can tell, the aluminum is legit. With any dealings with Chinese job shops, always make clear what you need/want and in what timeframe – for instance, I asked the shop explicitly whether or not they could ship before the Chinese lunar new year holidays, which is like right now. Well, they sure as hell did! Last year, I asked the same for the DeWut hardware; that one literally got out the door the day before closing.

The total turnaround time was 3 weeks. One week for the quote to slow-cook on MFG, and two for production and shipment (so really, prod took only a few days from payment because of shipping).

Okay! So, now that the Chinese have beat me to my own game, I’m going to start machining things.

Okay, fine, I’ll get up early to use a nice machine in a nice shop. Here’s the main weapon motor can being carved from a SOLID BILLET OF STEEL. I knew this was going to be tricky going in because of the extremely space-constrained nature of this motor, so one piecing it was preferable over a press fit anything. This is the rotor portion being made, where the magnets will eventually sit.

It took me a while to get used to 1. machining and 2. on something big again. I had forgotten that carbide loves going fast, and it took a tap on the shoulder and a “Dude, you should be running like 500 RPM on that at least” to kick me back in gear.

Much better. Now for the pulley side.

For the close-in pulley groove, I used a straight grooving tool in a cutoff bar holder (for left side clearance), but with the compound slide set to the V-groove half angle, and just fed very gently.

After cleanup of the ‘skirt’ of the rotor, which was unreachable in the first setup, I pitched the thing on an EZ-Trak style 3-axis CNC machine (the things based off Bridgeport mills) and conversationally bored the six rotor holes – conversationally as in WHY IN THE NAME OF BABY ROBOT JESUS HAVE I FORGOTTEN HOW TO USE THESE DAMN THINGS.

The completed rotor, sitting on top of the billet of steel from whence it was cast.

Time to line up the magnets and…. well, shit.

I typically don’t make full-circle magnet rotors unless I had already tried making one and know that the magnets fit. This little 2mm gap in the magnets is entirely made of manufacturing tolerance. The magnets have larger fillets than I expected, so they packed just a little bit closer together. For instance, if I were to make another of these with the same pile of magnets, I would know how much diameter to reduce by to get a clean fit.

Not a disaster, since all this entails is slipping a paper shim between the magnets when gluing.

I’m sick of Hobbyking motors shitting magnets on me like BurnoutChibi’s NTM motors. I know it’s entirely a matter of cheapening out on adhesive quality and magnet & rotor surface preparation since they need to make a zillion of these per day. For my own motor, I can take a little more care.

The stuff in the cup is some Aeromarine brand Epoxy mixed with a handful of colloidal silica filler. I don’t know what the actual amount was, but it looked like what I would have grabbed from the bag, but that stuff is sort of bad to come in contact with, so I used a cup instead. The silica filler increases the volume of the epoxy and makes it into a quasi-composite material for higher strength and space-fill ability. The mixture was made thick, so it won’t sag when I cure it on the radiators.

I laser cut a spacer to keep the first set of magnets in their proper spaces. This motor has 14 magnet poles, but each pole is made of two magnets. Two like-poled magnets really don’t like being next to each other, so I’m calling upon my old hub motor making tactics here. One set of magnets already solidly anchored will allow me to slip the rest in with ease.

What the magnet ring looks like with the spacer attached. I left this to bake on top of one of the radiators in the shop, since it’s still UNACCEPTABLY COLD here outside.

The next day, I came back and shoved the rest of the magnets in. With another little batch of epoxy, I made big filleted ridges on the inside face (closest to the six holes) to prevent the magnets from moving, then shoved and filled in as much of the epoxy as I could into the small gaps on the near side. I hope the combination of this, and gently sanding the faces of the magnets to be glued, will prevent them from falling off. This rotor will be spinning a healthy 12,000 rpm or so.

Left to do on the motor include making the hub that the stator mounts on, as well as winding the motor itself. This is the first motor I will have made with less than 10 turns per tooth….

Next up, drive hubs. I decided to take a super simple modular approach to this and carve them out of some steel hex. Because the elements involved, such as the wheels and sprockets, are all flat, my choice to retain them along the hub is just retaining rings.

Each hub, therefore, just entails 6 grooving and a cutoff operation, plus the center hole drill.

Here’s a completed hub, with the shoulder screw that will serve as the axle.

Soon after this picture was taken, I realized that there was nothing at all that I could tighten the shoulder screw against to keep the axle in the robot itself – recall the slotted axle mounting points. If I can’t tighten the shoulder screw, then the axle will just fall out. Imagine that happening in a match!

Oops – slight design oversight.

The backup plan is to open the hole in the hub to a little over 3/8″, and use a 3/8″ sleeve bearing over the shoulder screw as the spacer. Essentially, keeping the bearing stationary and spinning the wheel around it. There will be a bit more drag, but nothing an overdose of grease won’t overcome.

The plan executed.

I’ve also chamfered the sprocket teeth in this picture. The chamfer makes the tips of the teeth much narrow, such that the chain can stand some amount of misalignment. This is pretty critical to proper operation of chains and sprockets, especially if the tension can’t be guaranteed like the way I have it set up.

With the four wheels done, time to move onto something very exciting!

That started as a 5 foot long straight bar of aluminum.

With a powered roll bender, it becomes a 16″ hoop that goes around a certain not-quite-round robot. To form the hoop, I sized the bar with about 3-4″ of extra room on each end to accommodate the distance between rollers, and pass it back and forth between the rollers while tightening the center one each time. Gradually, the bar turns into a partial hoop.

The finished hoop

And with it stretched around the robot. Pretend-o-bot!

I need to cut off the ends and trim them to be flush next:

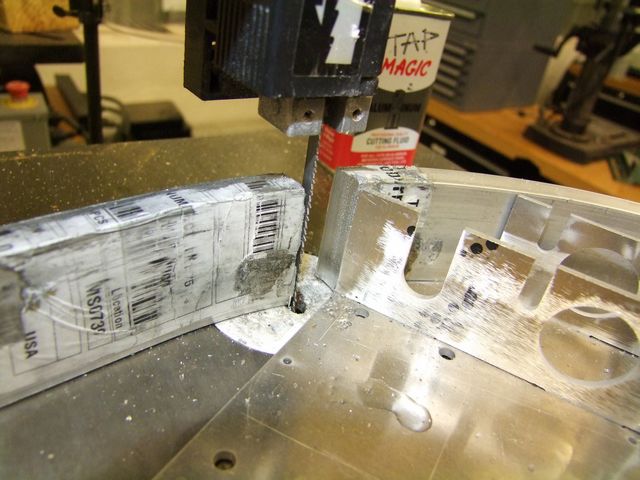

So I did it on one of the wimpy little Craftsman bandsaws I maintain in the shop for students to cut things like plastics and wooden dowels on.

Nobody can stand here and tell me one of those bandsaws can’t cut through 2″ of aluminum, because this took less than 15 seconds. It’s entirely about having the right blade, and keeping the cut lubricated. The blade is a variable-tooth 10-to-14 TPI bimetal type, and I kept pressure on the cut while squirting aluminum Tap Magic at it. Worked great!

To trim the rest of the excess, I broke out the spare angle grinder I bought when appraising gear reduction methods for Chibi-Mikuvan. I have fully integrated this into a shop tool, available only to students who pass a battery of “Dear GOD WHY DO YOU ACTUALLY NEED IT?” tests. I had armed it with a set of both steelcutting and nonferrous-metal cutting discs, so I broke one out for this occasion. When in doubt, abrasives backed by gratuitous power tends to cure most ills. I cut vertically, using the face of the 1/8″ top plate as a guide.

A bit of belt sanding to fit the edge and the front plate could fit flush. I might keep sanding this to close the gap between top plate and front plate more, but the “using abrasives on an aluminum guide surface” part took more out of the top plate than I would like. This edge may stay unwelded or be patched with a small round bar.

I bent the front wedge with a standard metal brake.

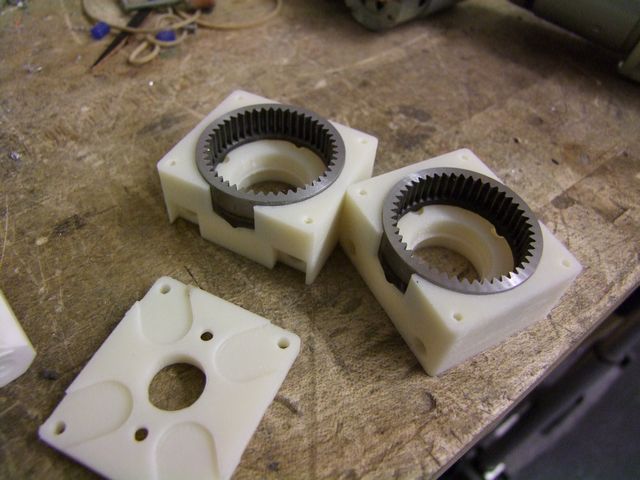

I moved onto finishing the drive motors. I’m staying with the 12 o’Clocker style “Angerboxen” design, which is a single-stage repackaged drill motor. To get the parts, I needed the following:

- Two 18v native 550 size drill motors, to be supplied by Harbor Freight drills (Null Hypothesis leftovers)

- Two 9 tooth pinions from a 36:1 drill gearbox, since the HF drills are 24:1. To be supplied by two random drill gearboxes on standby.

I took apart four drill motors and was amazed that between then were four different grease colors, plastic gear colors, pinion materials, and ring gear styles. Okay, China. Come on.

The gearcases, like on 12 O’Clocker, are made on a Dimension 3D printer out of ABS plastic. I carved off the ring gears on tinylathe.

(Try to tell me that this plastic is somehow worse than the shady nylon-like substance the original gearboxes were made from…)

I recycled the drill spindles into the output shafts. Again, the output sprockets are retained by ….. retaining rings. I love the cutoff bar I bought for Tinylathe because the width of the tool is correct to service the most common snap ring widths I use: 1/2″ and 12mm.

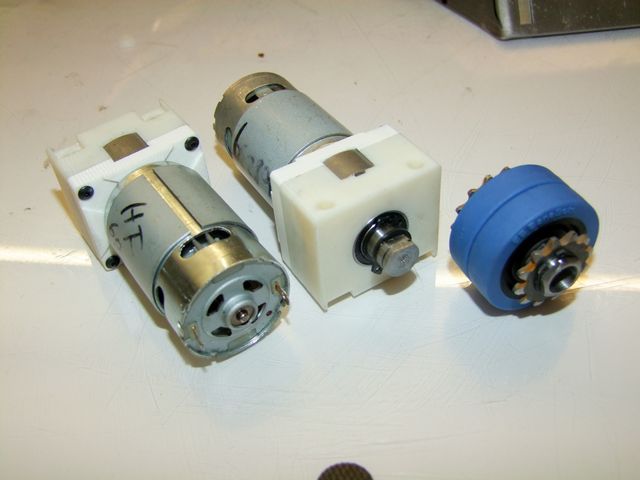

Here, I’ve used a pinion puller (background) to extract the 15 tooth pinions from the Harbor freight motors and replace them with the 9 tooth pinions from the other drills. Gearboxen have also been populated with metal output gears.

And here are the completed drive motors, after the D profile was milled onto the shafts. I have output sprockets, but they were cut improperly; I’ll need to remake them.

At this point, there are only 3 more major things to machine:

- The big center spindle and bearing holder block

- The blade spindle itself

- The motor’s stator hub

Minor things to do include:

- Make the battery retaining brackets

- Wind the stator ahead of time

I hope to knock these out during this coming week, such that when the frame gets back to me, I can immediately start dropping components in it!