It’s been nearly a year since my first visions of the Chuckranoplan.

Last time, knowing absolutely nothing about aeronautical design and lacking the funds and the testicular fortitude to just beast it, I decided to put off the thing until I became more familiar with the subject at hand and the physics and principles which govern ground effect flight. That, and I have no clue how to build something with surface curvature along more than 1 axis at the same time. Aircraft and boats don’t seem to be amenable to t-nutting, and that’s a problem. Somehow, I get the feeling that waterjetted aluminum plates and machined billet isn’t the way that most small watercraft and aircraft are manufactured.

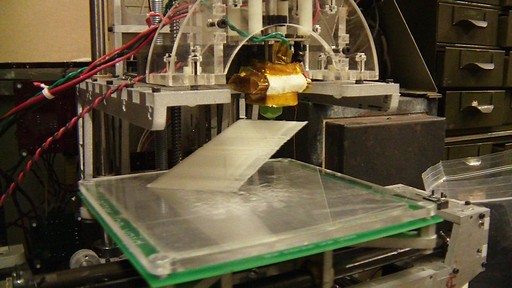

Now, months later, I still knowing nothing about aeronautical design, but I do have a 3d printer. I’ve also been researching GEV design as a background process, and kind of have an idea of how this is supposed to work. But, overall, I’m still without a means… intellectually, that is, to build a person-carrying craft.

So then why not start smaller? If the vessel is sufficiently small, I could print parts or templates for it. Many times. In short order. Design validation via model testing is a totally legitimate method of making sure your transport implement works before it goes off and kills dozens of people changes the way people think about getting around becomes Youtube-worthy. Besides, making a small model Chuckranoplan means I will finally be able to use Hobbyking parts for the purpose they were intended.

And so with a fresh install of Autodesk Inventor 2011, I hopped in and started playing with the more advanced geometric features I haven’t looked at before.

…

That’s when I discovered that my knowledge of Autodesk Inventor was really, really, really pitifully small. It’s enough to make stuff… but not, say, smooth stuff, or good-looking stuff. I seem to have designed myself into a corner with my Chinese puzzle building methods.

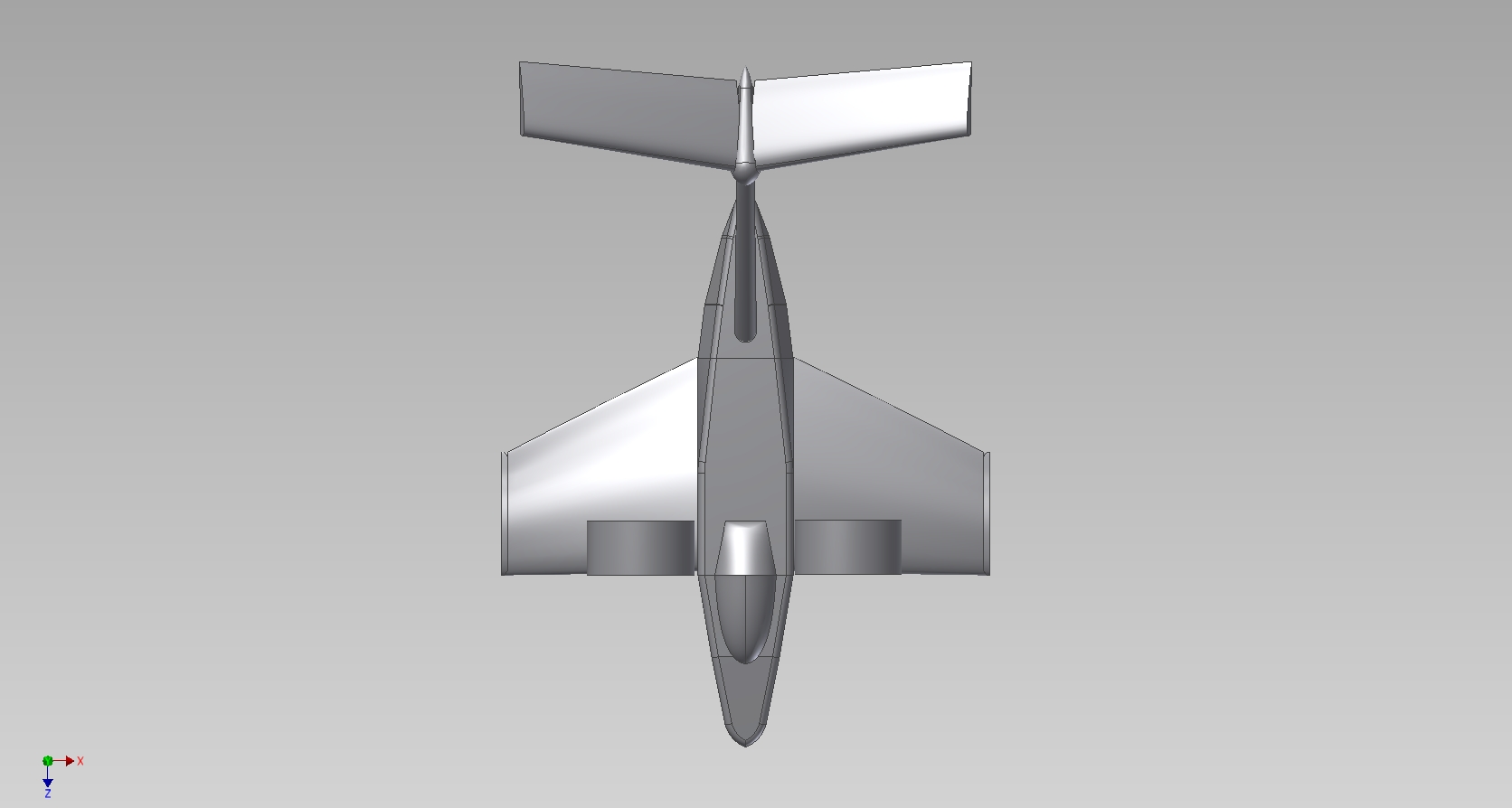

Without further ado, here’s μ-Chuckranoplan.

Hey! It’s kind of cute, isn’t it? I think I was trying to design both a conventional ekranoplan and a Lippisch-style delta wing at the same time, and succeeded in doing neither. For clarity, forward is down.

I discovered that either I’m doing it way, way wrong (more likely), or Inventor isn’t as well suited to smooth surface modeling as a program more geared towards animators and industrial designers such as 3DS. Basically, making the hull and airfoil profiles were a royal pain and very time consuming using multiple lofting operations. What made it worse was that while I had a nice airfoil profile picked out using Javafoil, I couldn’t get the sketch point import to function at all. I believe it’s a matter of Inventor wanting Real Microsoft Excel, not my Fake OpenOffice Not-Excel application.

So what does that mean? All the airfoil profiles on this thing were freehanded using splines until they looked right.

Yeah. Very scientific. But I think they’re okay.

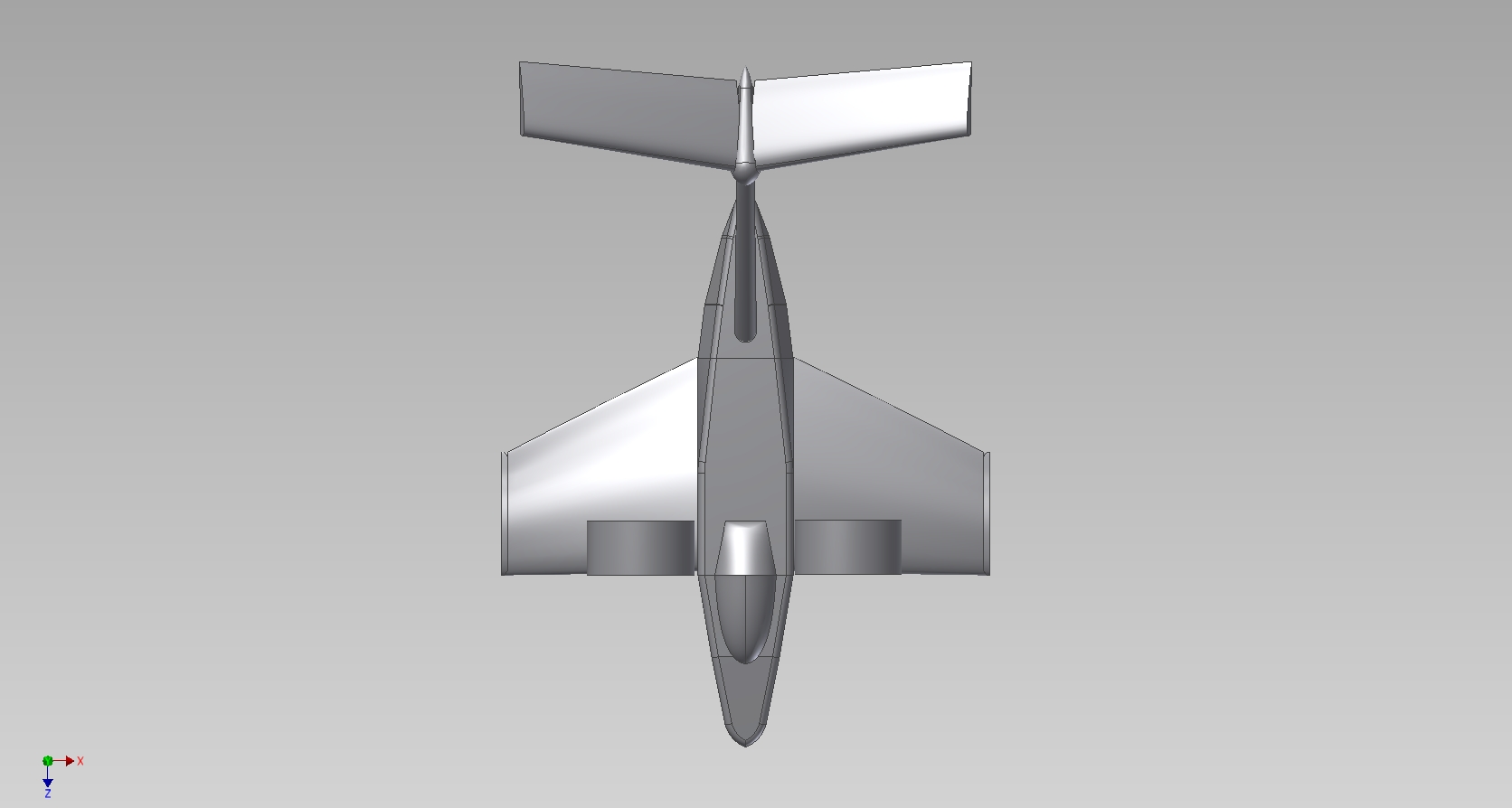

Here’s a side view of the design. The cylindrical blocks are stand-ins for some small 30mm-ID ducted fans I found on Hobbyking. I won’t be able to design the pylons or really even the shape of the things until I have them. While I would have pursued front-mounted fans (for PAR and badassery), putting those huge ducts in front of the “bubble” made the whole thing look incredibly derpy.

I already think delta-wing craft look derpy, so my design goal here was lessening the derp.

Such being the case, I’ve temporarily designated the twin fan location as immediately behind the “cabin” area. I haven’t done any fluid flow simulations, but I think they’re sufficiently out of the way of the main wing top surface.

They give the thing a mouse-ears effect, which makes it even cuter.

In this view, you can clearly see my utter failure at hydrodynamic design. I’m fairly certain the hull should actually be turned around – fatter at the front than at the rear, so to speak. Making all those loft profiles come together was also difficult. And of course the way I did it ruins any chance of making the craft body a continous smooth surface.

The model, when assembled, has a wingspan of 9 inches, a length overall of 12.25 inches (tip of nose to highest tip of tail in the very back), and a height of 5 inches. Since I’m limited to a print area of roughly 6″ x 6″, I can’t fire off the entire thing at once. The model is actually an assembly split into a few large parts. Each wing is separate, and the body itself is 3 pieces – the front nose portion, the middle (essentially the chunk from leading to trailing edge of the wings), and the back section. The vertical part of the tail, including the round thing, is another piece. Finally, each tail airfoil is separate. The interfaces will be made using inserted dowels and plenty of superglue.

It will be fun to test as a “throwie” model, but I’m going to print the segments as hollow shells to save weight anyway. Therefore, I can easily cut away a part of the outside to jam small flight electronics into it. The middle body cavity is probably the most amenable to this treatment. Incidentally, that’s where the center of gravity should be.

I’ve cleaned up the geometry a bit here, and also modeled the fan shrouds based solely on the Hobbyking product image. The only thing I know about it is that it’s 30mm inside and 40mm outside.

Note that this model has no control surfaces, because I’m not that sophisticated yet. So, the dual fans will also play a role in steering via differential thrust. For this reason, they might end up further out from the wing root, just for more leverage.

I’ve already tried printing one wing out of PLA plastic, and it turned out quite nicely. So I think I’ll just piece the rest of the model together as the week progresses and my HK parts arrive.

Oh, yeah, that was another criterion in designing much of the geometry – that it’s printable without support material. I think I did okay in that regard.

While my test prints will be in PLA since that’s what’s loaded into Make-A-Bot at the moment, I’ll probably order some white ABS plastic for more structural durability and impact resistance. Because I know I’m going to plant this right into a wall at top speed.

Hopefully in the near future I’ll become better versed in curved surface modeling, and the design will evolve. Then I’ll build one 40 times bigger.