It steers.

The differential was a short distraction project before I left for Atlanta. I didn’t *really* need it, but it was a neat thought experiment that would contribute to the vehicle if I had it. What’s more essential to the vehicle’s handling is the steering system, which I’ve sort of halfheartedly been working on for the past while.

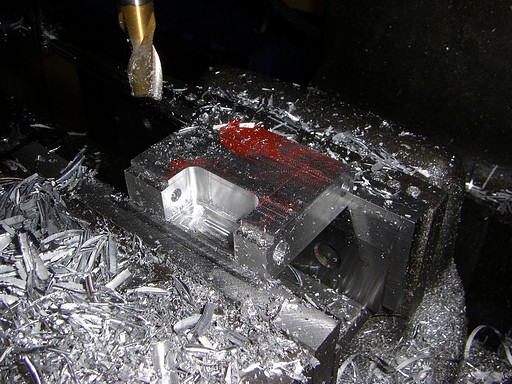

So over the last few days, I summoned the effort to finish said steering system. Another pound and a half of aluminum billet later…

It works! Because now the driver has a controllable degree of freedom, everyone in MITERS at the time took turns pushing/being pushed through the hallways. LOLrioKart is a big hit, even before it moves under its own power…

So here’s how it was done.

MORE BILLET! Here, the cap screw linkages have been joined. This 10″ long, half inch thick span of aluminum holds the cap screw heads in clamps at the ends, and has provisions for the Pitman link pivot pin in the middle. The cap screw sit in semicircular cutouts made by a ball-ended mill. To lock the linkages where they are, the clamps are tightened down. If I ever need to adjust the toe angle, I can loosen the clamps, turn the cap screws in or out slightly, then relock the clamp.

One more big chunk of aluminum comprises the Pitman link itself. Notice that the pin actually travels in a slot. This is because the pivot point of the Pitman link is slightly in front of the pivot point of the wheel kingpins. Each side of this contraption is its own unequal-length 4-bar linkage. Unfortunately, I can’t have a rigid front connecting link if this is the case.

So to work around it, what would normally be a pin joint is actually a slot. This means the steering response is nonlinear, but as the wheels can only turn around 90 degrees total, the nonlinearity is small enough to be neglected. I’m not going to care about a few degrees true deviation from a linear response when I’m flying across potholes at an unhealthy speed.

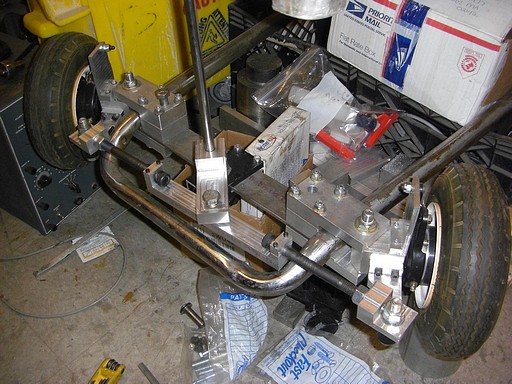

Completed bottom half of the steering system. That’s alot of shiny metal.

Some of my friends have expressed concern over the unhealthy amount of aluminum billet on LOLrioKart. This is often followed by giggly gossip along the lines of “He doesn’t know how to weld!”.

MITERS has a MIG welder that I have used on occasion, such as when a big crack opened up in one of the frame tubes on my bike. I don’t like welding for something like this – while it would be simpler, faster, and at this point lighter, it is just too permanent for a project whose design parameters change on a whim. It would also necessitate grinding off the chrome finish on the tube frame and adding dark, amorphous blobs of metal in its place. If I decided I didn’t like how something finished, dismounting it involves an angle grinder. Yes, I could have machined form-fitting steel pieces and welded them accordingly, but then why bother with the welding?

Aluminum goes fast on the machines anyway, and I think the disproportionately large blocks of shiny metal just give it a more unique appearance than the average tube-and-plate framed go-kart. If I had as regular access to CNC machinery, then the pieces would be significantly less blocky. For now, I’m more concerned with the functionality – I can add “features” later.

tl;dr weldin sux

Alright, the lower half is done. To the upper half!

Here’s the first of 3 parts to the upper steering wheel mounting system.

To avoid having “municipal bus syndrome“, I purchased a small universal joint and aimed to mount the steering wheel at an angle no less than 30 degrees from the vertical. Fortunately for me, the universal joint only seems to operate to that point anyway.

Either way, I needed to make the angled shaft support. We don’t have an angle vise, so I had to tilt the head on the Bridgeport. I hate doing this, since returning the head to dead vertical is a painful procedure involving jiggling a dial indicator. Usually I just eyeball it – works fine as long as I’m not taking massively wide facing cuts.

The finished part. This holds the steering column at 30 degrees. Two back-toback 3/4″ bore bushings, from Ãœberclocker’s arm pivot before I switched to ball bearings, will support the steering column. Along with the 1″ wide bushing of the middle support and the 5/8″ self-aligning bushing on bottom half, I think I’m all set for proper shaft support.

Here’s the second of three parts. This bridges the empty space between the angled shaft support and the front of the kart basket.

By this time, I had run out of 2″ x 1″ rectangular barstock. So I had to rummage through our stuff bins in order to come up with the half-processed stock for this piece. No, the crude milling marks on top are not mine, or the litttle stairstep at the edge.

You’ll see how it all goes together shortly.

And the third part is done. Now it should be making more sense.

The third part just sandwiches the kart’s wire frame between it and the spacing block.

Now let’s hook up the steering wheel to all this shafting.

I needed more 3/4″ shafting. Unfortunately, I used all of it for the rear axle and differential. Not wanting to dispose of the solid axle before I knew whether or not I was going to use it in the end, I stole a big 3/4″ bolt from the hardware bin and called it good. A trip to the bandsaw removed the threaded end and the head, leaving me with the meaty steel middle.

Next, I made the steering wheel adaptor. The steering wheel is a quick-release type for legitimate race karts. It has a 1″ hexagonal bore, in which sit 3 balls protruding through the vertices. A spring-loaded collar keeps the balls in that position, until it is pressed, upon which the balls are free to fall outwards a bit. Normally, these balls would be shoved into a groove cut into the steering column, so that if the collar isn’t pressed, the wheel is tightly retained on the column, but can be quickly removed simply by pressing the collar and yanking.

Luckily, I had a piece of 1″ hexagonal steel stock. The bore is a squish-fit (better than a press-fit!) for the 3/4″ boltshaft.

Here is the hex end grooved, and the other end of the bolt turned down to fit the 5/8″ bore of the universal joint. The hex stock was squish-fitted with a 5-ton arbor press.

So this is how it all goes together. When the three cap screws of the shaft support are tightened, the whole assembly is rock-solid. Notice the tongue-and-goove setup on the bushing block. This was to allow for the possibility of misalignment from my eyeballing. I could insert little shims in the gap to adjust the slack this way.

Incidentally, this is the 100th LOLrioKart build pic.

Now to connect the two sides together by pinning the shafts to the universal joint.

The lower shaft is 1/2″ in diameter and the universal joint takes 5/8″. The solution was a reducer bushing. Simple, but how to drill a hole in the same place in both? Optimally you’d have designed the parts beforehand to fit together.

This is how to not do it, but it worked in a pinch. I violently clamped the bushing against the shaft and stabbed a carbide 1/4″ endmill through both.

While I had a good endmill in the mill and the steering shaft right there, I added some Flats of Set Screw Gripping (+1?). This, along with the pinned universal joint connections and the hex bore of the steering wheel, makes sure there is a fixed angular relationship between said steering wheel and the front wheels.

Everything put together. I couldn’t find a real pin for the universal joint, so I made do with a random standoff and a random 1/4″-20 cap screw.

And the steering wheel is mounted! After a check of all the set screws, it was time to rock the hallways Flintstones style.

I am proud to announce that, even with our reckless disregard for health and safety, the death toll from this initial human-powered run was 0.

Although there WAS a close call with someone’s dog jumping in front of the kart, necessitating a near ass-dragging emergency stop from me.